Struggling with how to open lotion pump? See why smart buyers choose packaging that delights customers and keeps brand loyalty flowing.

Ever wrestled with a stubborn bottle, twisting and jabbing like you're defusing a tiny plastic bomb? That’s the drama behind “how to open lotion pump” . One bad pump and suddenly your product's five-star review is circling the drain.

Here’s where quality packaging becomes more than just skin-deep. It’s about those tiny mechanics—twist locks, spring tension, actuator design—that decide whether users feel delighted or duped.

According to Mintel's Beauty & Personal Care Packaging Report, over 61% of U.S. consumers say ease-of-use affects brand loyalty more than scent or formulation. You read that right—if it won’t open, they won’t reorder.

So we’re pulling back the curtain on lotion pumps: which types suit what products, how they're meant to be opened, and what smart buyers should demand from suppliers who claim “premium.”

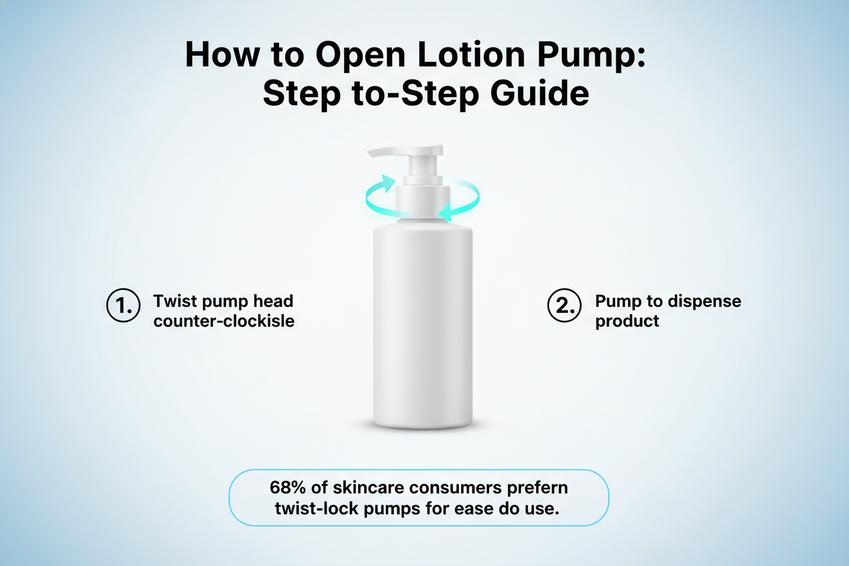

How to Open Lotion Pump: Step-by-Step Guide

Here's how to open lotion pump packaging the right way:

Identifying Different Pump Types: Lotion Pump Actuators and Dispensing Mechanisms

Understanding your pump type is half the battle when figuring out how to open lotion pump packaging. There are several common styles:

- Standard push-down pumps with locking collars

- Twist-to-unlock actuators, often found on hand soaps

- Airless dispensers, which use vacuum pressure instead of a dip tube

According to Mintel’s Packaging Trends Report Q2 2024, over 68% of skincare consumers prefer twist-lock pumps for ease of use and leak prevention. Knowing your pump's design helps you avoid forcing it open the wrong way.

Step 1: Preparing Your Product for Opening

Before diving into unlocking anything, get your setup right:

• Place the bottle on a flat, dry surface for stability

• Wipe off any oil or residue from the cap or collar area

• Check if there’s any plastic wrap or seal still covering the top

Step 2: Unlocking the Pump Mechanism with Ease

Now it’s go-time. Here’s how most lotion pumps unlock:

- Hold the lower neck firmly near the base of the pump head

- Twist the top portion counter-clockwise—usually about a quarter turn

- If nothing happens, gently pull upward while twisting again

- Still stuck? Try turning clockwise once before retrying counter-clockwise

Most pumps are designed this way for shipping safety, not user confusion! Don’t force it too hard—you might damage internal parts like the collar or actuator.

Step 3: Ensuring Smooth Actuation for Optimal Use

Once unlocked, test that baby out:

- Press down multiple times until product flows

- If air spits out first, keep pressing—it’s just clearing bubbles

- Make sure actuation feels smooth without resistance

Here’s what you're aiming for:

| Test Action | Expected Result | Troubleshooting Tip |

|---|---|---|

| First press | Air releases | Normal—continue priming |

| Second/third press | Product starts flowing | Keep pumping if slow |

| Resistance when pressed | Consistent feedback | Avoid pressing too fast |

A clean prime means your pump is ready for daily use—and you won’t have to fight it every morning.

Summary Tips for Daily Use After Opening

• Store upright to avoid leaks through nozzle gaps

• Clean dried product around tip weekly using warm water

• Don’t overtighten if re-locking—just enough to secure

Once you’ve figured out how to open lotion pump designs correctly, keeping them working well is all about simple habits.

Bonus Insight: Why Some Pumps Feel “Broken” When They’re Not

Some pumps appear jammed but aren’t faulty at all—they just need proper alignment between inner components like springs and valves inside actuators. If you feel resistance during twisting but no movement, try lifting slightly as you turn; this resets internal tension.

Knowing these tricks saves time—and keeps you from tossing perfectly good products!

Quick Recap Checklist Before You Toss That Bottle

✔ Did I remove all seals? ✔ Did I twist both ways before giving up? ✔ Is there dried product jamming anything? ✔ Have I tried pumping slowly five times?

If yes across all and still no luck—it might actually be defective (rare). Otherwise, now you know exactly how to handle even tricky lotion dispensers like a pro.

And hey—if you're dealing with premium skincare packaging like Topfeelpack's airless systems, some designs may skip traditional pumps entirely!

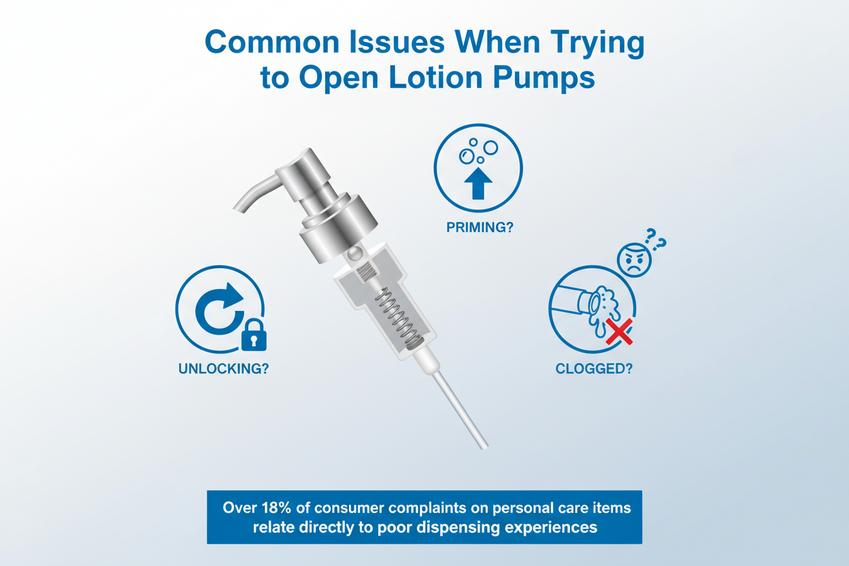

Common Issues When Trying to Open Lotion Pumps

Ever twisted and twisted but nothing came out? You're not alone—getting lotion pumps to work can be weirdly tricky.

Lack of Instruction: Understanding Cosmetic Pump Assemblies

- User confusion often starts with missing or unclear instructions. Many pump bottles skip the manual entirely, assuming users know how they function.

- A cosmetic pump typically consists of these components: — Pump head — Dip tube — Actuator spring — Housing chamber

- Design varies by brand, which means even if you’ve opened one before, another might trip you up.

The real kicker? Some are locked for shipping and need to be twisted just right to unlock the mechanism—not always obvious unless you’ve seen it before.

Here’s a quick way to avoid frustration:

- Check for an arrow near the neck—it often shows twist direction.

- Look underneath the cap for tamper-evident rings or seals.

- If nothing moves, don’t force it; some pumps require a gentle upward pull after twisting.

If you're wondering how to open lotion pump types with no guide, remember: it's all about understanding those small mechanical clues hidden in plain sight.

Difficulty in Actuation: Addressing Smooth Operation Challenges

Smooth operation isn’t guaranteed—even when you think you've done everything right.

▪️ New pumps may require several presses before anything comes out because of air pockets inside the chamber. This is called priming, and it's totally normal.

▪️ Excessive friction between internal parts can cause resistance when pressing down on the pump head, especially if manufacturing tolerances aren’t tight enough.

▪️ A dispenser that feels “stuck” might have dried product inside from shelf time—yes, even new ones can clog slightly during storage!

According to Euromonitor’s Q1-2024 Packaging Report, over 18% of consumer complaints on personal care items relate directly to poor dispensing experiences—a surprisingly high number rooted mostly in actuation issues rather than formula problems.

So next time your pump won’t budge? Try this:

- Prime it with slow full strokes (not quick jabs).

- Run warm water over it briefly if stored too long.

- Don’t press halfway—go full-down and full-up each time until flow begins.

Clogged Dosing Mechanism: Tips for Maintenance and Cleaning

Let’s face it—residue build-up ruins everything fast. Even top-grade pumps get blocked over time due to dried product stuck inside the nozzle or within the internal dosing mechanism.

Here’s what usually causes clogs: • High viscosity lotions that thicken at room temp • Infrequent use leading to stagnant buildup • Exposure to air causing crusty layers around the opening

Cleaning Tips That Work: – Remove pump from bottle completely – Soak it in warm water mixed with mild soap for about 10 minutes – Use a toothpick or cotton swab around narrow openings like the nozzle tip

| Problem Source | Symptom | Quick Fix | Frequency Needed |

|---|---|---|---|

| Thick residue | Slow/no dispensing | Warm soak + flush | Monthly |

| Air-dried product | Crusty nozzle | Manual pick + rinse | As needed |

| Formula separation | Uneven flow | Shake bottle + reprime | Weekly |

| Old container design | Leaky base | Replace or upgrade model | Once |

In short, knowing how to open lotion pump designs isn’t just about unlocking them—it’s also about keeping them running smoothly once they’re open. Regular maintenance goes a long way toward avoiding those annoying mid-use failures!

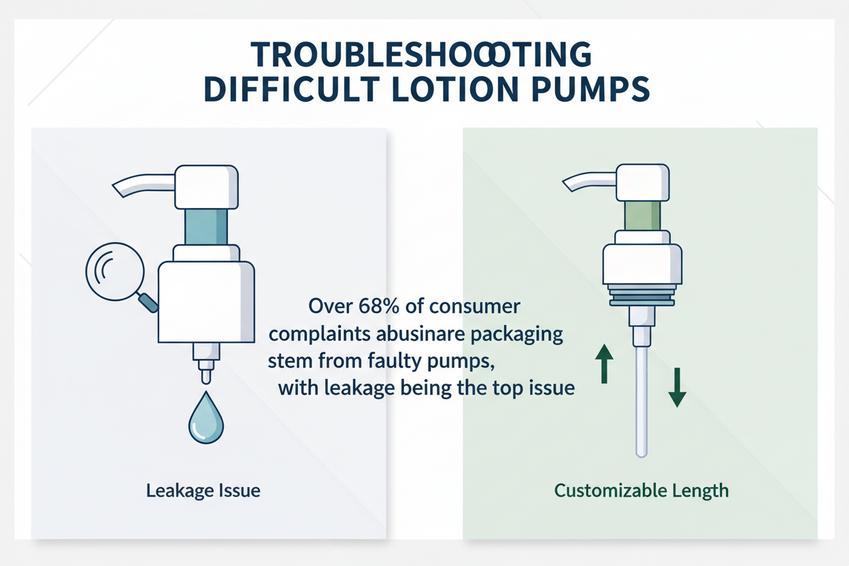

Troubleshooting Difficult Lotion Pumps: Solutions You Need

Getting stuck trying to figure out how to open lotion pump packaging or why it won’t work? Let’s break down the real issues and fix them fast.

Leakage Testing Procedures: Assessing Your Pump’s Integrity

A lotion pump that leaks can ruin your whole product experience—and your bathroom shelf. To keep things tight and tidy, manufacturers use several leakage detection methods:

- Visual inspections catch early signs of cracks or loose seals.

- Pressure testing simulates shipping conditions to expose hidden seal failures.

- Quality control teams run liquid flow tests to detect slow leaks you might not spot right away.

According to a 2024 report by Kline & Company, “Over 68% of consumer complaints about skincare packaging stem from faulty pumps, with leakage being the top issue.” That stat alone shows why proper defect analysis is critical.

If you're wondering how to open lotion pump bottles without triggering a mess, remember—design flaws in the seal could be the culprit, not you. Always check for tamper bands and tight closures before twisting anything open.

Unresponsive Pumps: Customizable Dip Tube Length Troubleshooting

When your lotion pump just won’t dispense anything—it’s not always broken. Sometimes it boils down to one thing: an off-sized dip tube messing with suction. Here's what you need to look at:

• Dip tube length: Too short? It can’t reach the product. Too long? It curls up and blocks flow.

• Priming issues: If air gets trapped during assembly, the pump won't build pressure properly.

• Tube customization: Trimming the dip tube slightly can solve most misfit problems instantly.

Also keep an eye on these common triggers:

- Misaligned spring mechanisms inside the actuator

- Blockages caused by thick formulas or dried product

- Repeated twisting when figuring out how to open lotion pump heads may loosen internal parts

Fixing an unresponsive pump doesn’t always mean replacing it—sometimes it's just about adjusting one small piece so everything clicks back into place.

How to Open Lotion Pump: A Visual Guide

Knowing how to open lotion pump bottles the right way can save time and keep things mess-free. Here's a visual guide to help you out.

Diagrams of Pump Types: Lotion Pumps vs. Airless Pump Systems

Understanding different dispenser types helps you figure out what you're working with when trying to open your lotion bottle. Not all pumps are built the same, and that matters.

- Lotion pump:

- Has a long dip tube inside.

- Requires twisting or unlocking before use.

- Common in body lotions and soaps.

- Airless pump system:

- Uses vacuum pressure instead of a dip tube.

- Delivers smoother product flow.

- Often used for serums or luxury skincare.

Post time: Jan-21-2026