For years, cosmetic packaging decisions followed a simple logic. Plastic offered flexibility and low cost. Glass delivered a premium feel. Paper supported sustainability narratives.

That logic is no longer sufficient.

Packaging today sits under simultaneous pressure from regulation, formulation stability, and supply chain efficiency. As a result, cosmetic packaging is being reconsidered not as a branding accessory, but as part of a product’s structural integrity.

Within this shift, cosmetic tin packaging is not resurfacing as a trend. It is being re-evaluated as a practical response to tighter constraints.

Why This Re-evaluation Is Happening Now

Three forces are converging.

First, regulatory accountability. Extended Producer Responsibility (EPR) and packaging waste regulations increasingly evaluate not just recyclability claims, but actual recovery and recycling performance.

Second, formulation sensitivity. The growth of waterless products, natural actives, and reduced-preservative systems has narrowed tolerance for oxygen, light, and moisture exposure. Packaging performance now directly affects product efficacy and stability claims.

Third, supply chain simplification. Brands are reducing material complexity. Fewer polymers. Fewer composite structures. More predictable sourcing and compliance.

These pressures explain why metal cosmetic tins are back on the table.

Barrier Performance: Where Cosmetic Tins Create Measurable Value

“Extended shelf life” is often cited, but rarely quantified.

In practice, shelf life depends on barrier engineering, not just closure design. Tinplate and aluminum offer near-zero oxygen transmission when properly manufactured and internally coated.

For certain oxidation-sensitive active ingredients, degradation rates in metal containers can be 2-3 times slower than in standard HDPE packaging,according to published packaging barrier studies.For high-value formulations, this difference translates into fewer stability failures, fewer customer complaints, and longer usable shelf life.

This advantage is most relevant for:

- Oil-based balms and salves

- Solid perfumes

- Anhydrous skincare sticks

- Active-rich or preservative-minimized formulations

Metal is not chemically inert by default. Food-grade or cosmetic-approved internal coatings are essential. They add cost and process steps, but skipping them introduces unacceptable formulation risk.

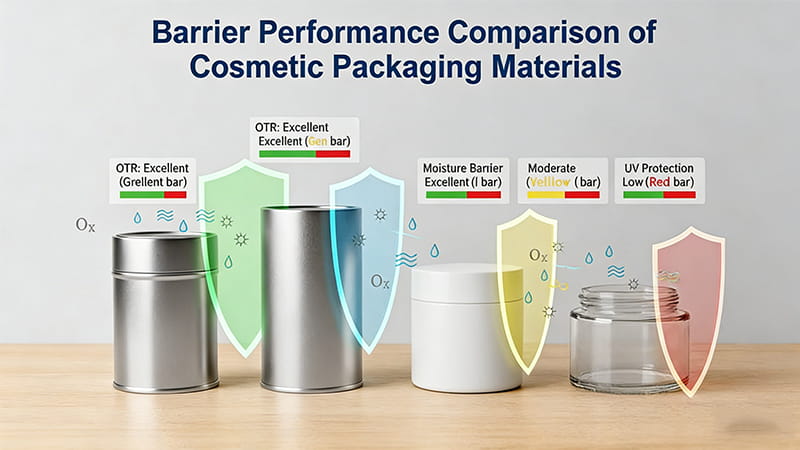

Barrier Property Comparison (Indicative)

| Material | Oxygen Transmission Rate (OTR, cc/m²/day) | Moisture Barrier | UV Protection |

|---|---|---|---|

| Tinplate | < 0.05 | Excellent | Complete |

| Aluminum | < 0.1 | Excellent | Complete |

| PCR PET | 5-10 | Good | Partial |

| HDPE | 15-30 | Moderate | Low |

| Glass (clear) | ~0 | Excellent | Low (unless coated) |

OTR values are indicative and vary by thickness and structure.

Durability and Distribution Risk

Packaging failures rarely occur on shelves. They occur in transit.

Plastic deforms under heat and load. Glass breaks under impact. Metal cosmetic tins absorb stress and retain shape.

For brands shipping globally or selling in warm and humid regions, this mechanical stability reduces secondary packaging needs and lowers damage rates. From a manufacturing standpoint, metal containers also offer predictable quality control-there is no post-forming deformation.

Durability here is not aesthetic. It is operational.

Hygiene, Reuse, and Practical Limits

Metal tins feature smooth, non-porous surfaces that are easy to sanitize. This supports higher hygiene standards for products applied directly to skin or lips.

That said, consumer behavior cannot be controlled. Reuse and cleaning practices vary widely.

From a risk perspective, however, cosmetic tins support tamper-evident features such as liners, press-fit seals, and shrink bands, which reduce both real and perceived contamination risk.

Sustainability Trade-offs: A Full Lifecycle Question

Metal packaging performs exceptionally well at end-of-life. Tinplate and aluminum are widely recycled and can circulate in closed loops with minimal degradation. In many regions, their actual recycling rates exceed those of plastics labeled “recyclable.”

However, metal production is energy-intensive. On a production-stage carbon footprint, metal often underperforms compared to PCR plastics or paper-based alternatives.

This makes the evaluation boundary critical-a point emphasized in

international packaging sustainability frameworks.

Is sustainability measured from cradle to grave, or from cradle to recycling?

The former may disadvantage metal.

The latter highlights its core strength.

Lifecycle Trade-off Comparison

| Evaluation Dimension | Metal Tins | Bio-materials | PCR Plastics | Glass |

|---|---|---|---|---|

| Production Carbon Footprint | Medium-High | Low-Medium | Low | High |

| Recycling Efficiency | Very High | Limited (industrial compost) | Medium | Very High |

| Material Degradation | Minimal | High | Medium-High | Minimal |

| Shelf-life Protection | Excellent | Moderate | Good | Excellent |

| Design & Branding Flexibility | High | Medium | Medium | Medium |

| Cost (Relative) | $$ | $$ | $ | $$$ |

No material wins across all metrics. Trade-offs are unavoidable.

Design Freedom and Tooling Reality

Metal tins support embossing, debossing, textured finishes, and high-resolution printing. These processes are mature and reliable.

What metal does not offer is unlimited flexibility without commitment.

Custom shapes require tooling. Tooling requires volume. Late-stage design changes are costly.

From a manufacturing perspective, this favors brands with stable SKUs and long-term planning. Metal packaging rewards decisive product strategy, not rapid iteration.

What Brands Often Underestimate

A few practical constraints deserve clear acknowledgment:

- Longer lead times compared to stock plastic packaging

- Fixed minimum order quantities

- Early finalization of internal coating specifications

Experienced cosmetic tin manufacturers can reduce friction, but these constraints do not disappear. Metal packaging favors planning over improvisation.

A Practical Cosmetic Packaging Decision Framework

There is no universal solution-only better alignment.

- If your priority is maximum protection for sensitive or active formulations, cosmetic tins offer unmatched barrier performance.

- If your priority is lowest upfront carbon footprint and cost, PCR plastic packaging may be more suitable.

- If your priority is luxury shelf impact with inert material behavior, glass packaging remains relevant when logistics allow.

- If your priority is rapid biodegradation and short product life cycles, certified bio-material packaging may be appropriate.

Metal occupies a pragmatic middle ground: durable, recyclable, protective, and operationally predictable.

Closing Perspective

This shift is not about nostalgia or aesthetics.

It reflects a broader rethinking of packaging as infrastructure, not decoration.

For brands that view packaging as a critical layer of product integrity-rather than a surface-level branding element-it is time to reassess cosmetic tin packaging with a more pragmatic, experience-driven lens.

Not because metal is perfect.

But because, under pressure, it is consistent.

FAQ

Q1:Are cosmetic tins suitable for all formulations?

No. Water-based or highly reactive formulations may require specialized coatings or alternative materials.

Q2:Do metal tins always extend shelf life?

Only when barrier properties match formulation sensitivity and appropriate internal coatings are applied.

Q3:Are cosmetic tins more sustainable than plastic?

It depends on whether sustainability is measured by production emissions or long-term material circularity.

Q4:What is the biggest risk when switching to metal tins?

Underestimating lead times, tooling commitment, and coating requirements early in development.

References

- The Future of Metal Packaging in Personal Care, 2024 – smithers.com

- Packaging and Packaging Waste Regulation (PPWR) – commission.europa.eu

- Packaging and the Environment – iso.org

- Guidelines on Packaging Sustainability – cosmeticseurope.eu

Post time: Jan-23-2026