Choosing the right types of bottle caps can save your cosmetic line from leaks, recalls, and TikTok shame—here’s why suppliers care.

You’d think choosing between the types of bottle caps would be as easy as picking a lid off your morning coffee—but nah, not in the packaging world. For high-volume cosmetic buyers juggling tight deadlines and even tighter margins, the wrong cap can mean leaks, loss, or worse—brand embarrassment on TikTok.

It’s not just plastic vs. metal; it’s performance under pressure, compatibility with fill lines, and Pantone-perfect finishes that make your branding pop while keeping costs sane. One mismatched thread or unreliable seal? That could sink a product line faster than you can say “batch recall.”

According to Smithers’ 2023 Packaging Report, over 72% of beauty consumers link packaging feel directly to perceived product quality. That means caps aren’t just closures—they’re credibility.

So yeah…choosing right matters big time—and we’re about to break it down like only insiders can.

Types of Bottle Caps: An Overview

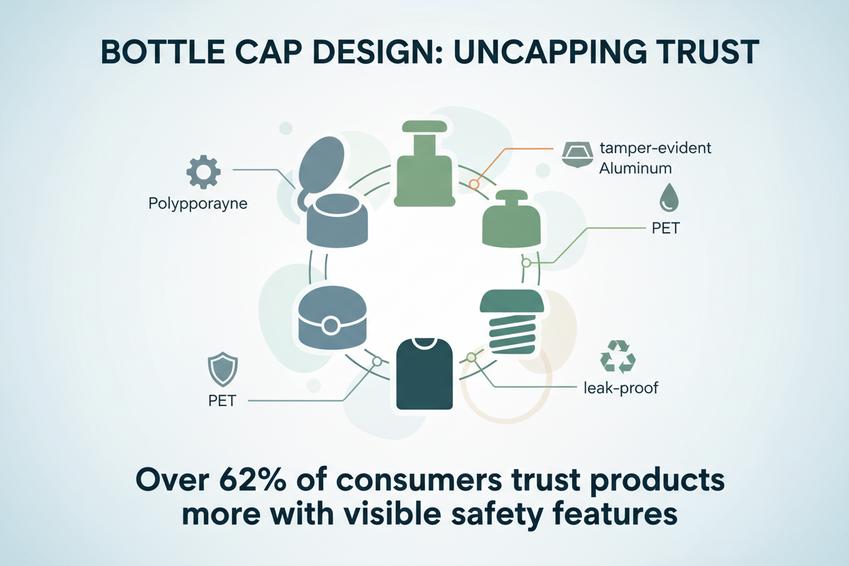

Let’s break down the most common types of bottle caps, their materials, and what makes them tick for different products and industries.

Common cap types: Flip top, Disc top, and Screw caps

- Flip tops are great for quick access—just pop it open with one hand.

- Disc tops let you control the flow, perfect for lotion bottles or shampoos.

- Screw caps twist on tight to lock in freshness.

These dispensing styles aren’t just about looks—they’re built for function. Whether it’s a thick conditioner or runny sanitizer, there’s a cap that fits just right.

Key material types for bottle caps: Polypropylene, Aluminum, and PET plastic

- Polypropylene (PP) – Lightweight, sturdy, and resists chemicals like a champ.

- Aluminum – Sleek finish with bonus points for being recyclable.

- PET plastic – Often used when clarity matters; think clear water bottles.

Each material has its own vibe and purpose—but all aim to strike the balance between durability and cost. Most modern caps combine aesthetics with sustainability, keeping both users and the planet in mind.

Size standards: 18/410 neck, 20/410 closure, and more

| Neck Size | Cap Type | Typical Use Case | Closure Fit |

|---|---|---|---|

| 18/410 | Screw cap | Essential oils | Tight seal |

| 20/410 | Flip top | Liquid soap | Snap-fit |

| 24/415 | Pump dispenser | Lotions | Secure twist |

| 28/400 | Trigger sprayer | Cleaning products | Lock ring |

These size codes might sound cryptic at first glance—but they’re crucial in matching bottles to the right closures. A mismatch? You’ll end up with leaks or loose tops—no bueno!

Special features of bottle caps: Tamper evident and leak-proof designs

Tamper-evident seals are like bodyguards for your product—they scream “hands off” if tampered with. Leak-proof designs? They keep your bag dry even when tossed around in transit.

According to Mintel’s Packaging Trends Report (2024), “Over 62% of consumers say they trust products more when packaging includes visible safety features.” That stat alone tells you how important these small design details really are in shaping consumer confidence.

From child-safe locking systems to induction-sealed liners, these features go way beyond basic functionality—they’re part security system, part brand promise wrapped into one tiny lid.

5 Essential Factors to Consider When Choosing Caps

Picking the right cap isn’t just about sealing the deal. It’s about function, feel, and fitting your product like a glove.

Material type: Why Polyethylene or ABS resin may suit your product

When it comes to choosing materials for different types of bottle caps, knowing what you’re working with is half the battle.

- Polyethylene (PE):

- Offers solid chemical resistance, making it ideal for aggressive formulas.

- Comes in high-density (HDPE) and low-density (LDPE) variants—each with their own flex and firmness.

- ABS Resin:

- Known for its high impact strength and durability under pressure.

- Perfect when you need a rigid feel that screams quality on contact.

PE works better for squeezable containers, while ABS is king for structured packaging for cosmetics needing sharp aesthetics.

Color options: Custom colors and the importance of Pantone matching

Color isn’t just decoration—it’s identity in a bottle. For brands juggling multiple types of bottle caps, consistency is everything.

- Pantone Matching System (PMS) ensures brand hues stay consistent across batches.

- Custom shades can match seasonal trends or limited-edition vibes.

- Color impacts consumer perception more than you think—blues suggest trust, reds spark urgency.

According to Mintel’s Packaging Innovation Report Q1 2024, “over 64% of consumers said color influenced their decision to pick one product over another on retail shelves.”

Whether you’re rocking flip-tops or twist-offs, make sure every cap color tells your story loud and clear.

Surface finish decisions: Glossy finish versus matte finish for visual appeal

Choosing between glossy and matte finishes isn’t just about looks—it’s also about how customers interact with your packaging.

• Glossy Finish: Reflects light beautifully; gives off a sleek, modern vibe that pairs well with high-shine labels. • Matte Finish: Offers subtlety; feels soft to the touch and aligns with minimalist branding trends. • Combo Finishes: Some brands use dual textures—matte body with glossy rim—for contrast that catches the eye fast.

| Finish Type | Texture Feel | Visual Impact | Common Use Case |

|---|---|---|---|

| Glossy | Smooth | High shine | Beauty/skincare |

| Matte | Velvety | Low glare | Organic products |

| Satin | Semi-smooth | Balanced glow | Premium lines |

For any kind of bottle cap design, pairing texture with color elevates both shelf appeal and tactile experience—two things that matter way more than most folks think.

Comparing Plastic Vs. Metal: Which Bottle Caps to Choose?

Choosing between plastic and metal bottle caps isn’t just about looks—it’s about function, feel, and fit. Let’s break it down.

Advantages of plastic caps

Plastic bottle caps are like the Swiss army knife of closures—super flexible and easy on the wallet.

- Lightweight design means less shipping cost and more convenience for consumers.

- They can be molded into countless shapes, offering excellent versatility in packaging styles.

- Available in a rainbow of colors, they support brand identity without breaking the bank.

- Thanks to modern polymers like HDPE and PP, they’re highly compatible with various beverages.

- Many options now come with child safety features or specialized dispensing options, especially in pharma or personal care.

Grouped by benefit: Functionality: Twist tops, flip-tops, squeeze-friendly—all possible with plastic. Cost: Mass-produced at lower prices than metal alternatives. Sustainability: Some plastics are recyclable—though not all—but innovations in biodegradable resins are pushing things forward.

If you’re balancing cost efficiency, ease-of-use, and design freedom, plastic might just be your go-to among all the different types of bottle caps out there.

Benefits of metal caps

Metal bottle caps bring a whole different energy—they’re tough, sleek, and built to last.

- Made from aluminum or steel, they offer serious strength against drops or pressure shifts.

- Their premium aesthetics make them popular for high-end spirits or cosmetics.

- Most feature built-in liners that allow for solid hermetic sealing, preserving freshness longer.

- There’s also the bonus of clear tamper evidence, which builds consumer trust right off the shelf.

- And let’s not forget—their high rate of recyclability makes them an eco-friendlier pick when handled correctly.

According to Euromonitor’s Packaging Trends Report (2024), “Metal closures have seen a 12% uptick in premium beverage segments due to their perceived value and durability.”

Grouped by material type: • Aluminum Caps – Lightweight yet corrosion-resistant; ideal for carbonated drinks • Steel Caps – Rugged choice with excellent barrier properties; often used in sauces or condiments

So if you’re eyeing longevity, upscale vibes, or airtight protection across various types of bottle caps, metal might just seal the deal.

FAQs about Types of Bottle Caps

What are the main types of bottle caps for cosmetics?

From a lotion’s gentle press to a shampoo’s quick pour, choosing the right cap keeps every experience effortless:

- Flip top caps: Quick one-handed opening—perfect on lotion bottles.

- Disc top caps: Controlled dispensing with style; suits serum bottles.

- Screw caps: Firm closure for cream containers needing safety in storage.

- Pump & spray caps: Functional elegance on shampoos and mists; designed for repeated daily use.

How do material choices shape performance and feel?

Polypropylene brings flexibility, Polyethylene offers softness—it feels warmer to the touch. Aluminum gleams with durability; PET plastic stays light yet resilient while ABS resin adds solid precision in threads and closures.

Why do tamper evident or leak‑proof features matter so much?

They speak directly to trust:

- Protects lotions in 20/410 closures from spills during transit.

- Assures customers—seal unbroken means purity untouched.

- Boosts brand reputation by combining tamper evident bands with BPA free materials.

Does size compatibility make a difference when ordering large batches?

Absolutely—the neck finish governs fit: 18/410 small openings suit delicate lip serum bottles; 24/410 fits robust pump dispensers like those gracing shampoo bottles; deeper threads such as 28/410 embrace heavier cream jars without compromise.

| Size code | Common pairing | Cap example |

|---|---|---|

| 18/410 | Serum bottles | Disc top cap |

| 20/410 | Lotion bottles | Flip top cap |

| 24/410 | Shampoo/Cream containers | Pump cap |

| 28/410 | Bulk creams | Screw cap |

How does surface finish influence perception?

The human hand remembers its touch and eye cherishes its shine:

- Glossy finish lends black glossy caps their bold premium charm.

- Matte finish whispers sophistication across white opaque lids.

- Soft touch wraps fingers in warmth for luxury skincare jars.

- UV coating protects custom colors via Pantone matching under bright display lights.

References

- Smithers’ 2023 Packaging Report – https://www.smithers.com/services/market-reports/packaging/the-future-of-global-packaging-to-2028

- Mintel’s Packaging Trends Report (2024) – https://www.mintel.com/insights/packaging/global-packaging-trends/

- Mintel’s Packaging Innovation Report Q1 2024 – https://store.mintel.com/report/us-color-cosmetics-market-report

- Euromonitor’s Packaging Trends Report (2024) – https://www.euromonitor.com/article/top-trends-shaping-pet-bottle-packaging-demand

Post time: Jan-20-2026