-

Common Technical Terms of the Extrusion Process

Extrusion is the most common plastic processing technology, and it is also an earlier type of blow molding method. It is suitable for blow molding of PE, PP, PVC, thermoplastic engineering plastics, thermoplastic elastomers and other polymers and various blends. , This article shares the technica...Read more -

Understanding of Conventional Packaging Materials

Common cosmetic plastic packaging includes PP, PE, PET, PETG, PMMA (acrylic) and so on. From product appearance and molding process, we can have a simple understanding of cosmetic plastic bottles. Look at the appearance. The material of the acrylic (PMMA) bottle is thicker and harder, and it look...Read more -

Packaging Surface Treatment Process: Screen Printing

We introduced the packaging molding method in “From the Molding Process to See How to Make Cosmetic Plastic Bottles“. But, before a bottle is placed on the store counter, it needs to go through a series of secondary processing to make itself more design and recognizable. At this time,...Read more -

Packaging Surface Treatment Process: Water Transfer Printing

Slowly immerse the sneaker in the water with "paint", and then move it quickly, the unique pattern will be attached to the surface of the shoe. At this point, you have a pair of DIY original global limited edition sneakers. Car owners also usually use this meth...Read more -

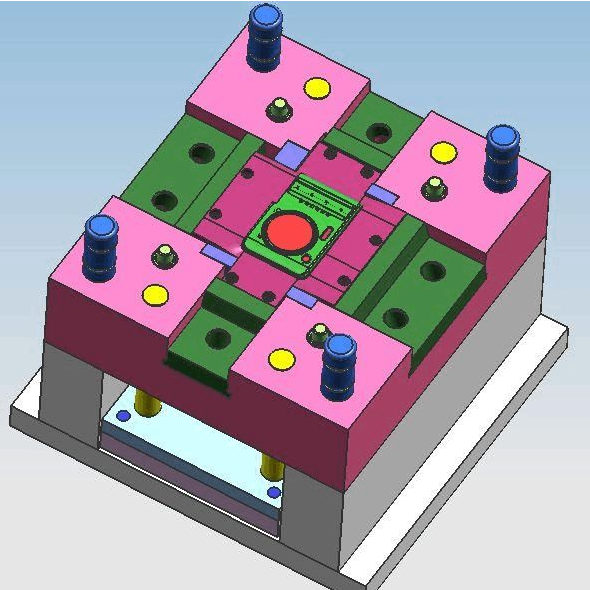

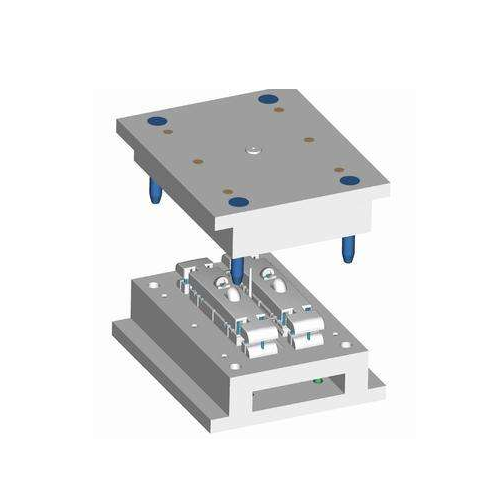

From the Molding Process to See How to Make Cosmetic Plastic Bottles

The plastic packaging material molding process in the cosmetics industry is mainly divided into two categories: injection molding and blow molding. Injection Molding What is the injection molding process? Injection molding is a process of heating and plasticizing the plastic (heating and melting ...Read more -

Types of Cosmetics

Cosmetics have many types and different functions, but in terms of their external shape and suitability for packaging, there are mainly the following categories: solid cosmetics, solid granular (powder) cosmetics, liquid and emulsion cosmetics, cream cosmetics, etc. . 1. Packaging of liquid, emul...Read more -

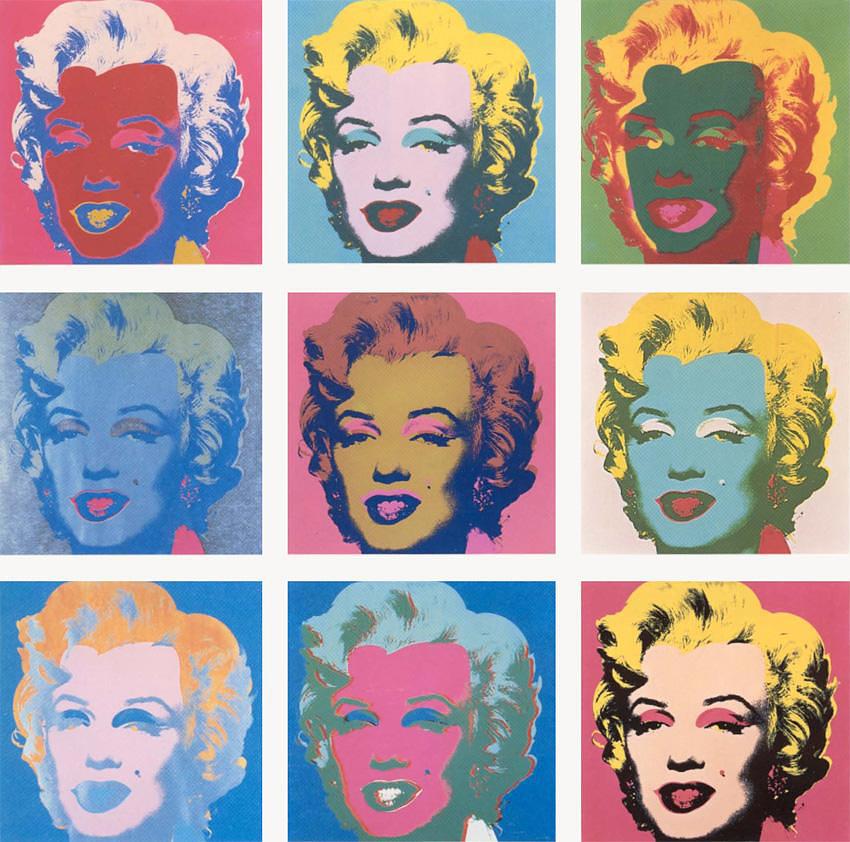

Packaging Makes Cosmetics More Attractive

The packaging of cosmetics contacts consumers earlier than cosmetics itself, and plays an important role in consumers’ consideration of whether to purchase. Furthermore, many brands use packaging design to show their brand image and convey brand ideas. There is no doubt that beautiful outer...Read more -

How to Choose a Suitable Cosmetic Bottle?

What kind of packaging is suitable? Why are some packaging and skin care concepts consistent? Why is good packaging not good for your skincare to use? It is important to choose the shape, size and color of the packaging wisely, but it is also important to consider factors such as durability and t...Read more -

The Role of Your Supplier in Packaging Branding

There are few industries out there with as much potential to develop loyal, die-hard customers as beauty and cosmetics. Beauty products are a staple in cabinets around the world; whether a person is going for an “I woke up like this” look or the avant garde “makeup is art you wear on your face” f...Read more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu