Big brands want more than pretty jars—beauty packaging companies now deliver eco-luxe designs that sell and save the planet.

The beauty packaging companies of 2025 aren’t just making containers—they’re crafting experiences, baby. And in a world where buyers care as much about what’s on the outside as what’s inside, brands can’t afford to slap lipstick on a landfill-bound tube and call it innovation. Big dogs want eco-smart solutions that still pop on shelves and feel luxe in hand.

“Refillables are no longer niche,” says Yoyo Zhang, Senior Product Developer at Topfeelpack. “They’re becoming the new standard for major cosmetic lines.” According to Mintel’s 2024 report, over 72% of U.S. consumers now expect sustainable features in their beauty buys—without sacrificing aesthetics or functionality.

It’s time to stop chasing trends and start partnering with suppliers who’ve already cracked the code.

Key Points That Matter: A Smart Snapshot for Beauty Packaging Companies

➔ Sustainability Reigns Supreme: From biodegradable materials like PLA to PCR plastics and mono-material designs, beauty packaging companies are leading the green revolution with eco-forward solutions.

➔ Refillables Go Mainstream: No longer just a trend, refillable packaging is now a must-have feature for modern cosmetic lines seeking long-term consumer loyalty.

➔ Design Meets Functionality: Compact containers and refillable formats prove that sustainability can still be stylish—eye-catching decoration techniques like metallization and color coating seal the deal.

➔ Tech Fuels Innovation: 3D printing enables custom, waste-reducing packaging, while blow molding innovations deliver lightweight options that lower transport emissions.

➔ Vegan Values Drive Demand: Transparency in ingredients and cruelty-free closures help vegan brands stand out—especially in skincare and cosmetics categories where ethics meet aesthetics.

Emergence Of Sustainable Materials In Beauty Packaging

Eco-conscious design is no longer a trend—it’s the new baseline for beauty packaging companies looking to stay relevant and responsible.

Biodegradable Options: The Rise of Eco-Friendly Packaging

- Biodegradable materials like PLA, PHAs, and starch blends are gaining serious ground.

- Compostable wraps and refill pods are replacing traditional plastic shells.

- Brands are even using mushroom-based foam for shipping protection.

→ These innovations don’t just look good—they break down without leaving harmful residue, making them ideal for clean beauty lines.

From sugarcane tubes to bamboo jars, each move toward eco-friendly packaging reflects a deeper shift toward sustainability across the supply chain.

Short runs with biodegradable formats allow indie beauty packaging companies to test green concepts fast—without sacrificing shelf appeal or performance.

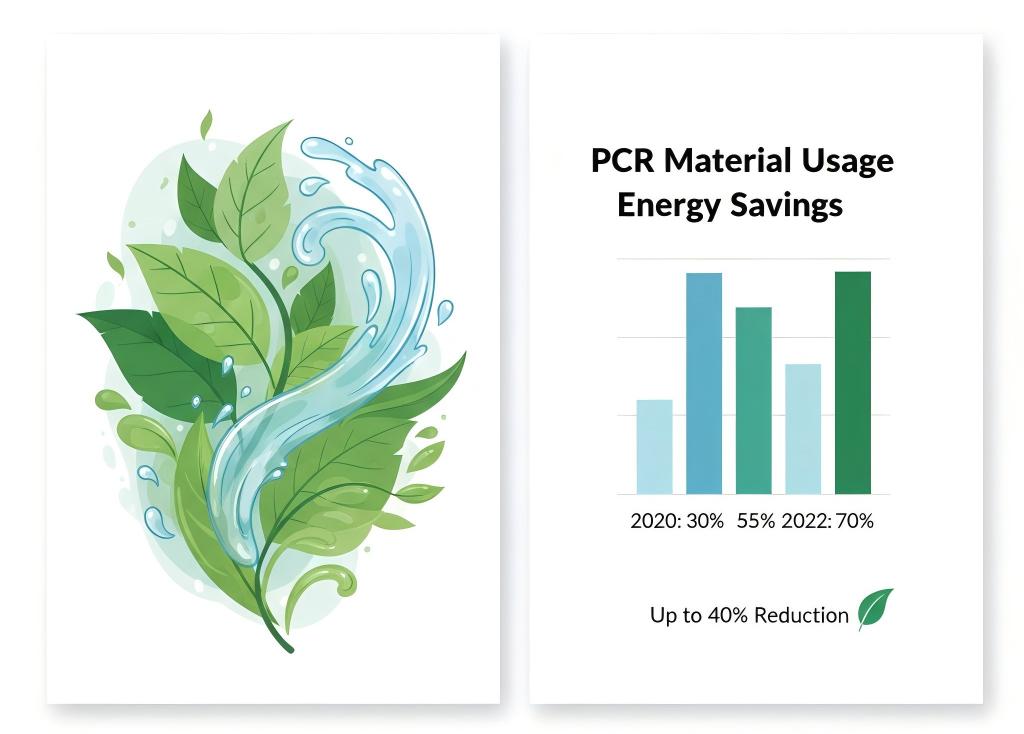

The Role of PCR Material in Reducing Waste

• Post-consumer recycled (PCR material) plastics like rPET and rHDPE cut virgin plastic use dramatically.

• Using recycled content helps brands meet sustainability targets while keeping costs competitive.

• More beauty packaging companies now partner with local recycling plants to secure consistent PCR feedstock.

Here’s how different types of PCR materials stack up:

| Material Type | Recycled Content (%) | Common Use Case | Energy Savings (%) |

|---|---|---|---|

| rPET | Up to 100% | Bottles, jars | ~60% |

| rHDPE | 25–100% | Tubes, closures | ~50% |

| rPP | Up to 70% | Caps, dispensers | ~35% |

| Mixed Plastics | Varies | Secondary packaging | ~20–40% |

Beauty brands are leaning into this not just for optics—it’s a real way to shrink their footprint while staying stylish on the shelf.

Exploring Mono-Material Solutions for Easy Recycling

Step 1: Choose one recyclable base—like all-HDPE or all-PET—for container and cap alike.

Step 2: Eliminate metal springs or mixed closures that confuse sorting machines.

Step 3: Design with disassembly in mind; make it intuitive for users to separate parts if needed.

Mono-material designs help streamline post-use processing at MRFs (Material Recovery Facilities). For beauty packaging companies aiming at zero-waste goals, this is one smart route that doesn’t compromise on aesthetics or function.

Glass vs. Plastic: Sustainable Choices in Beauty Packaging

Glass has long been seen as premium—and it’s fully recyclable without quality loss over multiple cycles. But it’s heavy, fragile, and energy-intensive during production.

Plastics? Lightweight champs that reduce transport emissions but often struggle with end-of-life recovery due to complex formats or contamination issues.

Still, both have their place depending on brand ethos and product needs.

As McKinsey & Company noted in its April 2024 report on sustainable consumer goods packaging trends: “The most sustainable option depends less on material type than on system compatibility and reuse potential.”

So when choosing between glass and plastic, beauty packaging companies must weigh more than just recyclability—they need full life cycle assessment, from raw extraction through disposal impact.

Innovative Designs: Attracting Today’s Eco-Conscious Consumers

Today’s shoppers want more than just pretty packaging—they want purpose. Here’s how smart design is reshaping what beauty packaging companies create.

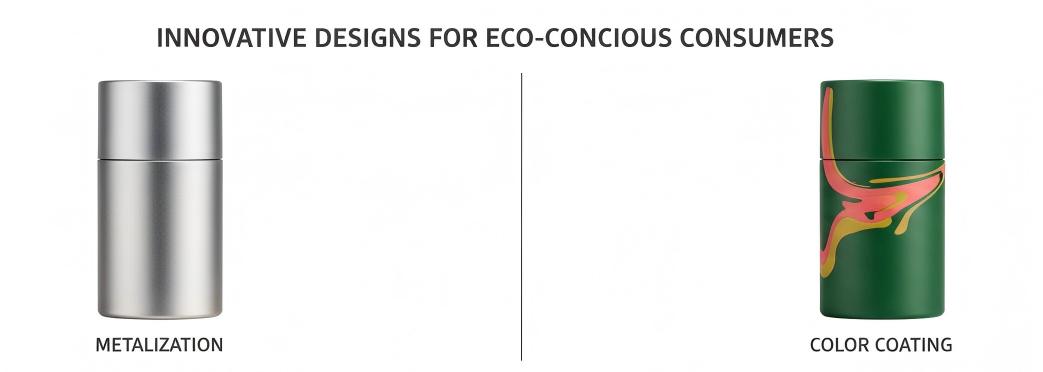

Eye-Catching Decoration Techniques: Metalization and Color Coating

- Metalization adds a sleek, reflective finish that screams premium without shouting waste.

- Color coating lets brands go wild with custom shades while keeping things eco-aware.

- These techniques boost shelf appeal and help products pop in a crowded aisle.

- Brands often combine matte finishes with glossy surface treatments for contrast.

- High-shine metalization can be water-based now, cutting down on harmful solvents.

• A well-executed decoration technique makes even refillable jars feel luxurious.

A bold look doesn’t have to come at the planet’s expense—just smarter materials and smarter design choices.

Short bursts of color or shimmer are often enough to catch the eye without overdoing it—especially when paired with recyclable plastics or glass alternatives.

Compact Containers: Style Meets Sustainability

Grouped by function and form, these innovations prove small can still be mighty:

– Compact containers made from biodegradable polymers reduce landfill load without sacrificing durability

– Magnetic closures eliminate plastic hinges, upping both style and recyclability

– Airless mini-pumps cut down on preservatives while extending product life

| Material Type | Avg Weight (g) | Waste Reduction (%) | Recyclability Rate |

|---|---|---|---|

| Bio-resin PET | 12 | 35 | 85% |

| Glass hybrid | 25 | 20 | 95% |

| PCR plastic | 10 | 50 | 90% |

Designers are shrinking the footprint—literally—with clever shapes that fit better in bags, drawers, and shipping boxes. For many beauty packaging companies, this is where style meets strategy.

Functional Design: Refillable Solutions for Modern Consumers

Refillables aren’t just a trend—they’re a movement with staying power:

- Snap-in cartridges make swaps easy—no mess, no fuss

- Twist-lock mechanisms prevent leaks during travel or storage

- Transparent refill indicators help users know exactly when it’s time to top up

Reusable components not only reduce waste but also build brand loyalty through repeat purchases—a win-win for both consumers and manufacturers.

Many modern buyers expect this kind of smart convenience baked into their beauty routines—and refillable solutions deliver that with flair.

Topfeelpack has been ahead of the curve here, offering sleek designs that merge usability with sustainability for today’s most forward-thinking labels in the global market of beauty packaging companies, suppliers, and innovators alike.

Top 3 Technologies Transforming Beauty Packaging Design

A wave of innovation is reshaping how beauty packaging companies approach design, sustainability, and personalization.

3D Printing to Create Custom Packaging Solutions

Beauty packaging companies are leaning into 3D printing not just for prototyping but full-on production. It’s more than a flashy gimmick—it’s changing the game.

- You can now get ultra-personalized containers shaped around your brand story—think bold curves, intricate textures, or even initials molded right in.

- With on-demand production, brands cut back on warehouse space and overstock waste.

- Less material is wasted since only what’s needed gets printed.Some startups are using this tech to test new shapes without investing in expensive molds—just tweak the file and reprint.

And here’s where it really shines:

| Feature | Traditional Molding | 3D Printing | Impact on Beauty Brands |

|---|---|---|---|

| Setup Cost | High | Low | Faster market testing |

| Design Flexibility | Limited | High | Unique product identities |

| Waste Generation | Moderate | Low | Eco-conscious appeal |

| Time to Market | Weeks | Days | Agile product launches |

This isn’t just a fancy upgrade—it’s a shift in how beauty packaging companies think about speed, flexibility, and style.

Blow Molding Innovations for Lightweight Containers

Beauty packaging companies are ditching chunky plastic shells thanks to smarter takes on blow molding, making things lighter without losing strength.

• Materials like PET and HDPE are being reformulated with recycled content while keeping that sleek finish consumers love.

• New mold designs allow thinner walls without compromising shape retention during shipping or shelf display.

• Advanced air-pressure control means fewer defects per batch—less waste, more consistency.

Grouped by benefits:

Sustainability Boost

- Use of bio-based polymers

- Reduction in resin weight up to 30%

- Compatibility with post-consumer recycling systems

Cost & Efficiency Gains

- Lower shipping costs due to lighter units

- Shorter cycle times during manufacturing

- Fewer returns from cracked or warped bottles

Design Innovation

- Sculpted necks and curved bases now possible at scale

- Integration with smart caps or sensor tags

- Transparent finishes while still using tinted materials

These upgrades aren’t subtle—they’re helping beauty packaging companies redefine what “eco-luxe” looks like today. Even Topfeelpack has started experimenting with hybrid blow-molded formats that merge elegance with efficiency.

The Shift Towards Vegan Packaging Options In Beauty Industry

The move to vegan beauty isn’t just about the formula—it’s reshaping how products are packaged, labeled, and even closed.

Ingredients Transparency: The Vegan-Centric Approach

Transparency is no longer a bonus—it’s expected. With more folks checking labels than ever, especially those buying from beauty packaging companies, brands are getting serious about showing what’s inside their jars.

• A full breakdown of ingredient lists—not just the INCI names but also their origins—is now standard.

• Consumers want to know if that glycerin is plant-derived or synthetic. They’re not playing guessing games anymore.

• Certifications like “Certified Vegan” or “Cruelty-Free” help build trust fast. But they’re not enough without clear sourcing info.

→ Many brands now post sourcing maps right on their product pages to show where their ingredients come from. That kind of transparency? It sticks.

Some indie beauty packaging suppliers have even started embedding QR codes into labels so customers can scan and get real-time updates on ingredient sourcing and ethics reports.

And as Mintel noted in its April 2024 Global Beauty Report, “Ingredient origin disclosure has become a key purchase driver for Gen Z consumers, with over 63% saying it directly affects brand loyalty.” That’s not a trend—that’s a shift in power.

Vegan-Friendly Product Category: Cosmetics and Skincare

Vegan-friendly products aren’t niche anymore—they’re everywhere from lip balms to night creams. And the best part? You don’t have to sacrifice performance for principles.

Group A – Core Features of Vegan Cosmetics:

- Vegan cosmetics use zero animal byproducts—no beeswax, carmine, lanolin, or collagen.

- They’re often packed with plant-based actives like algae extract or botanical oils.

- Most formulas are designed around minimalism—fewer ingredients but higher potency.

Group B – Key Benefits Driving Adoption:

- Ethical assurance through cruelty-free makeup testing policies.

- Skin-soothing effects thanks to natural formulations with fewer allergens.

- Alignment with sustainability goals via eco-conscious production methods.

Group C – What Shoppers Are Looking For Now:

- Labels that clearly state “100% vegan” without vague marketing fluff.

- Brands that partner with transparent beauty packaging companies offering recyclable containers.

- More options across categories—from SPF moisturizers to long-wear foundations—all under the umbrella of vegan skincare innovation.

With so many choices available today, shoppers can build an entire routine using only clean, ethical products—and they know exactly what they’re putting on their skin. No more mystery fillers or hidden animal derivatives hiding behind scientific names.

Eco-Friendly Closures: Pumps and Sprayers in Vegan Brands

Sustainable closures aren’t just good PR—they’re becoming essential for any brand claiming eco-conscious values. Especially those tied to vegan ethics.

Short Segment A — Why Closures Matter More Than Ever:

Small parts like pumps and sprayers usually fly under the radar—but they’re often made of mixed plastics that can’t be recycled easily. That’s changing fast.

Short Segment B — Smart Solutions Gaining Ground:

Many brands now opt for mono-material pumps made entirely from PP plastic—easier for recycling facilities to handle without sorting headaches. Others go further with refillable designs that screw off easily for re-use—a win for both cost savings and waste reduction.

Short Segment C — What Makes It “Vegan Packaging”:

It goes beyond materials; it includes avoiding adhesives tested on animals or rubber seals derived from animal fats. Even your average sprayer needs scrutiny when you’re truly committed to ethical design principles rooted in veganism.

In fact, some forward-thinking beauty packaging companies are exploring fully biodegradable pump systems using starch-based polymers—and while still niche, these innovations hint at where the industry is headed next.

FAQs about Beauty Packaging Companies

What sustainable materials are beauty packaging companies using more often now?

Sustainability isn’t just a trend—it’s an expectation. More brands are turning to:

- Post-consumer recycled (PCR) plastics like PET and HDPE, giving waste new life

- Bioplastics such as PLA that break down under the right conditions

- Glass, which feels luxurious and is endlessly recyclable without losing quality

These choices aren’t only good for the planet—they’re reshaping how consumers connect with products.

Why are mono-material containers gaining popularity in large-scale orders?

Because simplicity works. When a bottle or jar is made from one material—say, all PET—it’s easier to recycle. No need to separate layers or remove incompatible parts. For big buyers juggling sustainability targets and logistics costs, this kind of efficiency matters.

How do refillable systems help brands build stronger customer loyalty?

Refillables invite people into something bigger than a purchase—a ritual. A glass serum bottle you keep on your vanity becomes part of your routine. The snap of replacing a cartridge or pod feels satisfying—and responsible. Over time, these little moments add up to trust.

Are there vegan-friendly options for pumps and sprayers in beauty packaging?Yes—and they’re getting better every year:

- Plastic pumps made entirely from polypropylene avoid animal-based lubricants.

- Metal-free designs improve recyclability while keeping formulas safe.These details matter deeply to cruelty-free brands whose customers read labels closely—not just on ingredients but components too.

Can blow molding really make eco-conscious packaging more efficient at scale?Absolutely—it’s not just about speed; it’s about precision with less waste. Blow molding creates lightweight bottles quickly using minimal plastic per unit—which means lower shipping emissions and cost savings across continents when you’re producing thousands at once.

Do most beauty packaging companies offer 3D printed prototypes before full production runs?Many do now—and it changes everything during development. Holding that prototype compact in your hand lets you feel its weight, test how the lid clicks shut, see if the applicator fits smoothly against skin… It brings ideas out of digital sketches into real-world decisions before committing big budgets to tooling molds.

References

[The Clean Beauty Market & The Rise of Conscious Cosmetics - mintel.com]

[Excellent CO2 balance for rPET made by PET Recycling Team - petrecyclingteam.com]

[Mono Material Packaging: Key to Sustainable Cosmetics - virospack.com]

[The push for sustainability packaging is real—and complicated - mckinsey.com]

[3D Printing in Cosmetic Market Size, Share, Growth, Report 2025 to 2034 - cervicornconsulting.com]

[Global Beauty & Personal Care Predictions: 2026 & Beyond - mintel.com]

Post time: Nov-19-2025