From luxe serums to body wash, choosing the right bottle top types can save sales and reputations—because no one loves a leaky disaster.

You wouldn’t wear sneakers to a black-tie event, right? Same goes for your packaging—especially when it comes to bottle top types. The wrong closure on a luxe serum or thick foundation can tank the customer experience faster than you can say “leaky purse.” These little lids may seem minor, but they’re the gatekeepers of hygiene, shelf life, and brand reputation.

Skincare formulas are getting fancier by the minute—think retinol-packed elixirs and probiotic sunscreens—and with that comes pressure to seal them up tight without losing that ‘ahh’ moment of opening. Flip-tops for body wash? Cool. But airless pumps with UV protection for anti-aging creams? Now we’re talking big-league decisions.

In fact, according to Topfeelpack’s senior product engineer Joyce Lin (2024), “95% of return cases in overseas markets trace back to poor sealing compatibility—not formula failure.” That’s not just numbers—it’s your margins on the line.

Discover 5 Surprising Bottle Top Types Revolutionizing Skincare Packaging

You’ll never look at a skincare bottle the same way again. These five bottle top types are changing how we apply, preserve, and even feel about our daily routines.

Airless Pump Systems with Dosage Control and UV Protection

- Prevents product oxidation by keeping air out.

- Offers precise dosage control, so no more waste.

- Built-in UV protection shields formulas from light damage.

The combo of PMMA outer shells and ABS inner parts makes this pump feel premium while staying practical. It’s a go-to for sensitive or active skincare blends that need long-lasting freshness. And yeah—no clogging drama here.

Dropper Caps in Glass and PP for Precision Serums

- Glass pipettes = zero contamination risk.

- PP collars = lightweight but sturdy grip.

- Narrow tips = accurate dosing every time.

Perfect for sticky serums or oils where you don’t want to overdo it. These dropper caps make your morning routine feel like chemistry class—but in a good way.

“Precision dispensing closures like droppers are driving growth in the serum packaging segment,” according to Mintel’s 2024 Beauty Packaging Outlook.

Spray Pumps with Fine Orifice Size for Even Application

• Delivers a soft, even mist—no blotches, no mess

• Calibrated orifice size ensures consistent spray pattern

• Paired with foam liners to stop leaks cold

These spray pumps aren’t just functional—they’re satisfying to use. Whether it’s toner or facial mists, they distribute evenly without soaking your face like a garden hose.

Roll-On Applicators Designed for Targeted Skincare Formulas

Start with a stainless steel ball tip that glides effortlessly over skin. Add an HDPE bottle base that’s both squeezable and durable. Then finish it off with tamper-evident seals that guarantee freshness from shelf to skin.

This type of roll-on applicator is perfect for eye serums or spot treatments—anywhere you want cooling precision without using your fingers.

Disc-Top Caps Balancing Leak Resistance and Daily Convenience

- Flip open fast during your morning rush

- Snap shut tight enough to toss into gym bags

- No drips thanks to pressure-sensitive liners

These everyday heroes work best on lotions and shampoos where ease matters most. Made from tough PP or HDPE, these disc-top caps mix function with simplicity—and they hardly ever leak unless you forget to close them properly!

4 Key Bottle Top Types to Consider

Choosing the right bottle top types can make or break your product’s first impression. Here are four that stand out for both function and flair.

Screw Caps in PP and Aluminum with Induction Seal Options

- Screw caps offer a tight seal that keeps contents fresh.

- Made from either PP material or sleek aluminum material, they’re versatile across industries.

- Pairing them with an induction seal adds tamper resistance and prolongs shelf life.

- Twist-on mechanism means easy resealing.

- Compatible with heat-sealed liners for added protection.

- Available in glossy or matte finishes to match your brand vibe.

• Ideal for pharmaceuticals, oils, and beverages thanks to their durability.

These bottle tops are perfect when you need airtight security without sacrificing style. Topfeelpack offers custom color-matched options that blend branding with practical sealing power.

Pump Dispensers Featuring ABS Actuator Design and Gasket Seal

You want smooth, mess-free dispensing? That’s where these come in strong.

- The built-in gasket seal prevents leaks even during transit.

- An ergonomic ABS actuator ensures effortless use every time.

- Adjustable output volume suits everything from lotions to hand sanitizers.

• Works well for personal care, skincare, and high-viscosity liquids.

“Consumer preference is shifting toward functional packaging—dispensers ranked highest in ease-of-use surveys,” according to Mintel’s 2024 Packaging Trends Report.

With these stylish pump-style bottle tops, Topfeelpack helps brands deliver performance customers can feel with every press.

Flip-Top Caps Using HDPE with Tamper-Evident Seal

Quick open-close action meets peace of mind here:

- Snap-hinge design makes one-handed use possible.

- Molded from durable HDPE material, ensuring long-term resilience.

- Built-in tamper-evident seal shows if the product’s been opened before purchase.

These flip-style cap designs are popular on shampoos, sauces, and gels because they blend convenience with safety cues buyers trust. Plus, they come in all sorts of neck sizes to match different bottle formats—no more guessing games at the filling line!

Dropper Caps with Controlled Orifice Size and Glass Pipettes

This type screams precision—and a little luxury too:

- A calibrated tip controls flow via an exacting orifice size, drop by drop.

- Paired with sleek glass pipettes, these are ideal for serums or essential oils.

- Customizable lengths fit various bottle depths without splashing or waste.

• Adds a premium feel that enhances user perception instantly.

Whether you’re selling CBD tinctures or high-end skincare elixirs, this kind of dropper-style cosmetic applicator gives users confidence in dosing—and elevates your brand’s look while doing it.

Top 3 Benefits of Flip-Top Pumps

Flip-top pumps are more than just a packaging trend—they’re a practical upgrade that makes everyday products easier, cleaner, and better looking.

One-Hand Operation with Secure Flip-Top Cap Closure

No one likes fumbling with bottles when their hands are full. Flip-top pumps make life simpler by offering one-hand dispensing, so you can easily access your product without the hassle. The flip-top cap clicks shut for a secure closure, keeping messes at bay and ensuring smooth, convenient use every time. Whether you’re in the shower or mid-cooking, that quick snap gives you both control and product protection—no leaks, no spills.

Enhanced Hygiene Through Pressure Sensitive Liner Sealing

When it comes to hygiene, there’s no room for compromise. These pumps come equipped with a pressure sensitive liner, acting as a barrier against dust and germs. That extra layer means better contamination prevention, which helps extend shelf life and maintain freshness preservation. The liner also adds a subtle but effective form of tamper evidence—boosting consumer trust while locking in quality.

According to Mintel’s 2024 Packaging Trends Report, “Consumers are increasingly prioritizing packaging that signals cleanliness and safety without sacrificing convenience.”

The result? A boost in perceived value and actual performance through smarter sealing tech.

Custom Finishes: Matte Finish, Soft-Touch Coating, and UV Coating

Looks matter—especially on crowded store shelves. With options like sleek matte finish, velvety soft-touch coating, or glossy high-shine from a durable UV coating, brands can elevate their packaging game fast. These custom finishes don’t just deliver eye-catching style; they enhance the overall feel too. That added texture amps up the unboxing moment while offering long-term wear resistance thanks to advanced surface treatments.

It’s where design meets durability—and customers definitely notice.

Throughout all these benefits, flip-top pumps adapt across various bottle top types, making them compatible with countless designs while staying user-friendly. When choosing between different bottle, top, or types of closures, this pump style consistently delivers on function and form alike.

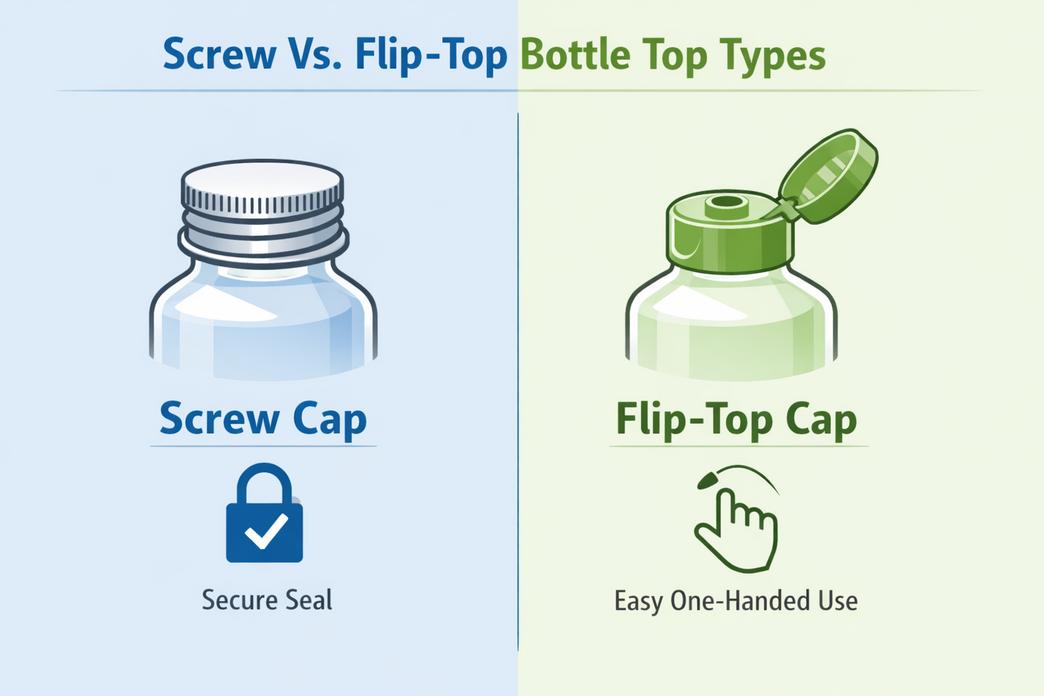

Screw Vs. Flip-Top Bottle Top Types

A quick guide to two wildly different yet equally useful bottle top types—each with its own perks, quirks, and best-use situations.

Screw Cap

The screw cap is the go-to for a reason—it’s simple, tight, and dependable. Its threaded closure screws directly onto the bottle’s neck using a continuous thread, creating a secure seal that resists leaks and keeps freshness locked in. You’ll spot these on everything from pill bottles to sauces. The materials vary—most are made from PP or aluminum depending on what they’re sealing. Some even come with built-in tamper-evident features or options for controlled dispensing, making them great for both safety and ease of use.

“Consumer preference still leans toward screw caps in pharmaceuticals due to their perceived reliability and compatibility with child-resistant closures.” — Mintel Packaging Trends Report 2024

Whether it’s the diameter of the opening or compatibility with heat induction liners, this cap type fits a wide range of bottle necks without fuss.

Flip-Top Cap

When convenience wins out over tradition, the flip-top cap steps up. This design features a built-in hinged closure, often paired with a small tab for easy flick-open action—ideal for one-handed use during multitasking moments. The snap shut mechanism provides satisfying feedback while helping preserve contents inside.

You’ll mostly see these made from HDPE or PP, depending on what kind of product needs sealing—from lotions to condiments. They often include tamper-proof elements or foam liners under the lid for added protection. Thanks to their controlled dispensing orifice, they’re perfect when you want clean pours without mess.

This style prioritizes fast access and smooth actuation—because nobody wants to wrestle with packaging when they’re in a rush.

FAQs about Bottle Top Types

1. Which bottle top styles are most common in skincare packaging?

A balance of design and utility defines them:

- Pump Dispenser & Spray Pump: For serums or toners needing dosage control and UV protection.

- Dropper Cap: Glass pipette with PP collar gives elegance and precision.

- Flip-Top Cap & Disc-Top Cap: Quick access while maintaining tamper-evident integrity through pressure-sensitive liners.

Each serves a ritual—from gentle squeeze to measured pump—turning daily use into small ceremonies of care.

2. What materials elevate both function and style in bottle top designs?

Each material carries personality:

| Material | Characteristic Use | Distinct Touch |

|---|---|---|

| Polypropylene (PP) | Durable, heat-resistant | Smooth lightweight texture |

| Aluminum | Luxury look for high-end branding | Cool metallic presence |

| ABS / PMMA | Accepts electroplating for glossy finishes | Refined visual depth |

| HDPE & Surlyn | Flexible yet strong; ideal for roll-ons or caps exposed to stress | Comfort under repeated fingertips |

The subtle shine of PMMA or the satin calm of aluminum transforms ordinary lotions into keepsakes on a vanity shelf.

3. How does sealing influence product freshness during storage or travel?

Think of seals as silent guardians:

① Induction Seal — Locks out air entirely, lengthening shelf life; perfect partner for screw caps.

② Gasket Seal — Cushions against vibration during transport; often found beneath disc-top caps.

③ Foam Liner & Shrink Band — Add layers of safety at retail display; signals purity before first twist open.

These unseen protectors ensure the fragrance you love today greets you unchanged months later.

4. What finish options help brands stand out on crowded shelves?

Artistry in textures brings emotion to touch:

★ Matte Finish: Quiet confidence that softens reflections under daylight tests photography beautifully.

★ Glossy Finish w/ UV Coating: Bright mirror tone amplifies brand colors beside clear glass bottles.

★ Metallic Finish & Soft-Touch Coating: One gleams like jewelry, the other invites lingering fingers—opposites crafting identity together through sensory contrast.

Decorations such as hot stamping or silk screening add final flair akin to signing one’s name on every cap.

5. Why is checking dimensions critical before mass orders?

Behind smooth operation lies numerical harmony:

1️⃣ Confirm Neck Finish Size (20/410) fits your chosen bottle thread count precisely—tight enough without strain.

2️⃣ Review uniformity in color batches to keep branding consistent under store lighting variations.

3️⃣ Match each cap’s height, diameter, and actuator design for reliable closure torque across thousands produced.

One millimeter off can shift perception from refined craftsmanship to careless alignment—a reminder that even engineering has artistry stitched inside it.

Post time: Feb-18-2026