When the Cosmetic Business goes big, packaging becomes a high-stakes performance—precision, drama, and 200K bottles waiting for their cue.

The Cosmetic Business isn’t just about creams and colors—it’s theater. It’s a stage where your product gets one shot to woo the customer under fluorescent grocery lights or in the scroll of an Instagram reel. And like any star performer, it needs the right costume. Packaging is that costume. But when you’re ordering 100,000 units and not ten vanity jars off Etsy, suddenly things get real… industrial.

Bulk buyers wrestle with quirks that indie brands don’t—like how a millimeter misprint on a lipstick tube can cost you thousands, or how shipping delays from your supplier in Guangdong can derail an entire launch calendar.

“Packaging at scale is precision choreography,” says Elaine Zhu, Senior Project Lead at TopfeelPack (2024 Q1 production report). “You’re balancing branding with blow molding tolerances while staying inside per-unit cost targets.”

5 Key Steps To Launch Your Cosmetic Business

Ready to turn your beauty idea into a real cosmetic business? Here’s how to build it from scratch—one smart step at a time.

Step 1 – Define Your Cosmetic Product Range and Brand Vision

Your brand vision isn’t just a vibe—it’s the soul of your cosmetic business. Start by locking down what kind of products you want to offer. Are you into clean skincare, bold makeup, or haircare with a twist?

- Pinpoint your hero product: serum, lipstick, cleanser?

- Match your product line with your ideal target audience

- Build a story around it—your “why” and what makes it different

Once you’ve nailed that, shape the look and feel: minimal chic or loud and artsy? Let this guide every decision ahead.

Step 2 – Select Glass, Plastic and Aluminum Packaging Materials

Choosing cosmetic packaging is more than picking bottles—it’s about aligning form with function and brand values.

✔️ For luxury appeal? Go with glass.

✔️ Want lightweight convenience? Plastic’s got you.

✔️ Need durability plus recyclability? Think aluminum.

Tie this back to your sustainability goals or cost strategy. Topfeelpack offers diverse packaging options tailored for indie brands trying to scale without compromising on quality or aesthetics.

Step 3 – Create Custom Packaging With Graphic Printing and Custom Molds

Split this into two key layers:

A. Design Aesthetic & Branding

- Use bold colors or minimalist tones depending on your identity

- Add layered textures or unique finishes like matte or glossy

B. Functional Ergonomics & Shelf Appeal

- Custom molds let you shape bottles that stand out—and feel good in hand

- Graphic printing ensures every label screams premium

With the right combo, even small-batch runs can look high-end—and scream shelf-ready confidence.

Step 4 – Ensure GMP Compliance and Perform Rigorous Material Testing

To keep your cosmetic business legit, safety isn’t optional—it’s everything. Here’s how:

- Get familiar with local cosmetic regulations

- Align operations with GMP compliance

- Test packaging under pressure—literally:

- Heat resistance

- Drop tests

- Seal integrity checks

This prevents leaks, lawsuits, and customer complaints before they start. Your customers trust what touches their skin—you should too.

Step 5 – Optimize Inventory Management and Logistics Planning

Running out of stock mid-launch? Nightmare fuel. Keep things smooth by managing supply like a pro.

- Use digital tools for real-time tracking of SKUs

- Plan shipping routes early to avoid delays

- Work closely with suppliers on lead times

Bundle these efforts into one tight system so you’re not scrambling during peak sales seasons—or worse—launch day itself.

Whether you’re launching a lip balm empire or skincare startup, getting logistics right keeps the whole machine running without hiccups.

Topfeelpack can help streamline inventory planning through scalable packaging solutions that grow as fast as your brand does.

Understanding The Cosmetic Packaging Industry: What You Need To Know

Get the inside scoop on how packaging choices shape your cosmetic business—from materials to sustainability trends.

Packaging Materials Impact on Brand Perception and Cost

- Paperboard gives off a natural, eco-conscious vibe.

- Aluminum tubes scream premium but can hike up costs.

- Plastics are flexible and cheap, but not always planet-friendly.

- Brands targeting eco-focused consumers often lean into paperboard or biodegradable plastics for that earthy feel.

- Luxury lines go for glass or brushed metal to create a high-end experience.

- Mass-market products tend to favor plastic for its affordability and scalability.

Choosing sustainable materials can also open doors to new markets and loyal customers.

A brand using matte-finish aluminum might be seen as sleek and modern, while kraft paper cartons suggest simplicity and care. Material is more than function—it’s your first impression.

Short-term cost savings from plastic may lead to long-term image damage if your audience values green practices. Think of material as part of your brand voice.

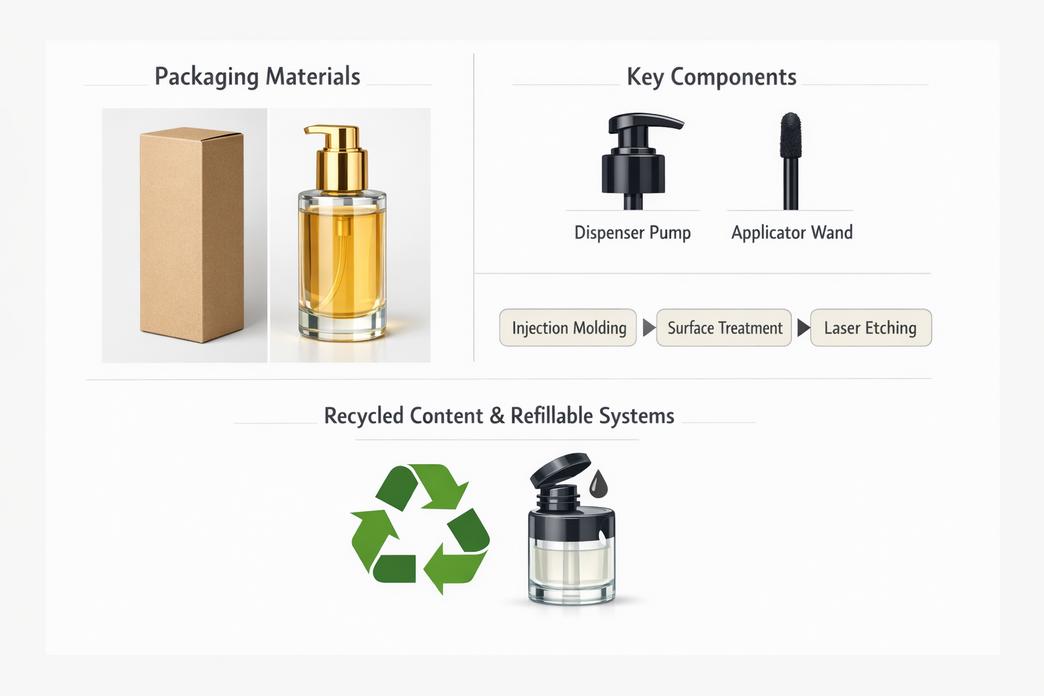

Exploring Key Components Like Dispenser Pumps and Applicator Wands

• A solid pump mechanism means fewer spills—and happier users.

• Wand design affects how much product gets picked up each time.

• Inner seals keep formulas fresh longer by blocking air exposure.

Dispenser pumps aren’t just functional—they influence how customers feel about using the product daily. A smooth pump action feels luxe; a sticky one? Not so much.

Applicators like doe-foot wands or silicone tips enhance user control—especially in lip glosses or concealers. These little things impact repeat purchases big time.

Innovations in Manufacturing From Injection Molding to Surface Treatment

- Start with advanced injection molding for precise shapes and minimal waste.

- Add unique finishes like soft-touch coating or metallic foil stamping for visual pop.

- Use laser etching instead of labels—sleek, durable, and tamper-proof.

Now group those steps:

- Functional Foundation:

- Precision molds reduce defects.

- Less scrap means lower production costs.

- Aesthetic Enhancements:

- Surface treatments boost shelf appeal.

- Custom textures encourage tactile engagement.

- Long-Term Value:

- Durable finishes resist wear during shipping.

- High-end touches elevate perceived value instantly.

These methods let even small-scale cosmetic businesses stand out without blowing the budget.

Industry Trends Around Recycled Content and Refillable Systems

• Post-consumer resin (PCR) is becoming standard in many packaging lines.

• Refillable systems are gaining traction with skincare brands aiming at zero-waste goals.

• Biodegradable containers offer both branding perks and regulatory advantages in some regions.

More indie brands now bake sustainability into their DNA—not just marketing fluff but real changes like compostable jars or refill stations at retail points.

Consumers are watching closely: if your packaging looks eco-friendly but isn’t recyclable, you’ll hear about it online fast. Smart moves here build trust—and loyalty—for any growing cosmetic business aiming to scale sustainably.

How To Choose The Right Cosmetic Packaging Supplier

Finding the right packaging supplier is a game-changer for any cosmetic business. Here’s how to make sure you’re teaming up with the best.

Evaluate Manufacturing Processes Including Blow Molding and Extrusion

To get packaging that matches your brand’s vibe, take a close look at their manufacturing processes:

- Do they offer blow molding, extrusion, and other scalable techniques?

- Can they handle detailed decoration like silk-screening or hot stamping?

- Are custom molds an option, or are you stuck with stock designs?

- Ask for samples from previous runs.

- Tour their production line—virtually or in person.

- Check if they can scale as your cosmetic business grows.

→ If a supplier can’t explain their process clearly, it’s probably a red flag.

Topfeelpack has in-house tooling capabilities that let brands tweak packaging without starting from scratch—super handy when you’re building out product lines fast.

Verify Quality Standards With ISO Certification and Leakage Prevention Testing

Quality isn’t just about looks—it’s about safety and consistency too. Confirm that your supplier checks all the boxes:

- Do they have valid ISO certifications?

- What kind of material durability tests do they run?

- How often do they conduct leakage prevention testing?

According to Mintel’s 2024 Packaging Report, “Over 72% of consumers say product integrity influences repeat purchases in beauty categories.”

That stat alone shows why quality control matters for every cosmetic business owner trying to build loyalty.

Assess Supplier Logistics Capabilities From Lead Times to Warehousing Solutions

Your packaging could be perfect—but if it arrives late, you’re toast. Solid logistics can make or break your launch schedule:

• Do they offer global shipping support?

• Can they provide flexible warehousing options near your fulfillment centers?

• What’s their average lead time for reorders?

Break it down like this:

- Short-term needs: Fast turnaround on limited runs

- Ask about expedited production slots

- Check real-time inventory tracking tools

- Long-term goals: Scalable solutions as your product line expands

- Look into volume-based pricing models

- Negotiate storage terms for seasonal surges

When choosing a partner like Topfeelpack, you’re not just buying bottles—you’re investing in supply chain reliability tailored to your evolving cosmetic business model.

FAQs about Cosmetic Business

1. How can I start my Cosmetic Business using effective packaging strategies?

A clear vision begins with material choice and ends with customer touchpoints.

- Glass containers bring elegance to serums; plastic bottles fit budget-focused lines; aluminum tubes signal durability.

- Add emotion through graphic printing, soft surface finishes, or tight-fitting caps closures that echo brand personality.

- Before mass rollout, conduct GMP compliance checks, material testing, and a final durability assessment—a safety net before stepping on stage.

2. Why is ISO certification essential when selecting packaging partners?

Think of it as trust made tangible: every pump, tube, or box shaped under control.

- Ensures each batch born through strict injection molding, steady extrusion processes, and refined surface treatment steps meets uniform quality.

- Anchors traceability—from tiny applicator wands to hidden sealing mechanisms—so deviations are quickly revealed.

- The mix of audit data and hands-on inspection keeps your credibility sharper than any jar’s edge.

3. How do sustainability initiatives influence customer perception in cosmetics?

In eco-aware circles, the story behind the bottle matters almost as much as what’s inside it. ♻️

• Packaging infused with recycled content or strengthened by post-consumer resin echoes care for our planet.

• Brands adopting biodegradable materials, integrating lightweight packaging, or experimenting with graceful refillable systems create long-lasting emotional loyalty—a modest gesture amplified by conscience.

4. Which factors improve efficiency in global sourcing for cosmetic packaging?

Supply rhythm decides how steady your shelves stay stocked across continents:

- Tighten flow through smart inventory management, shortening waits between production runs.

- Base stocks near hubs via regionalized warehousing solutions, feeding consistent exports through streamlined customs channels.

- Real-time order tracking adds harmony between brands and factories—a silent dance of predictability known as true “lead time optimization.”

Factor Impact Key Practice Supplier proximity Shorter transit times Hub-based storage Tech-enabled workflow Accurate forecasts System-linked scheduling Coordinated logistics planning Lower freight costs Shared distribution networks 5. What role does customization play in differentiating a young Cosmetic Business portfolio? Distinct form defines recognition even at arm’s length: rounded jars whisper softness; angular bottles promise precision.

➤ Use unique shapes from precise custom molds.

➤ Balance emotion through hue harmony crafted by thoughtful color matching.

➤ Blend function into art using fine‑touch dispenser pumps, balanced weight ratios, and an ergonomic silhouette finished by radiant decoration techniques.*

Each decision imprints identity—the magic where chemistry meets charm—and turns simple containers into storytellers worthy of their formulas within.

Post time: Feb-17-2026