When it comes to eye cream packaging, customers aren’t just looking for pretty lids and shiny labels—they want proof that what they’re putting near their eyes is safe, untouched, and fresh as a daisy. One busted seal or sketchy-looking cap? That’s all it takes for shoppers to toss your brand aside like last season’s mascara. No joke—according to Mintel's 2023 Beauty Packaging Report, 85% of U.S. consumers say tamper-evident features directly affect their buying decisions.

Quick Notes on Trust-Building Trends in Eye Cream Packaging

➔ Airless Pump Systems Preserve Product Integrity: These closures prevent oxidation and contamination, keeping sensitive eye creams fresh and hygienic from first use to last.

➔ Metallic Finishes Elevate Brand Image: Pantone-matched metallics not only enhance shelf appeal but also signal luxury and quality, reinforcing consumer confidence.

➔ Eco-Friendly Materials Reinforce Ethical Credibility: Using paperboard cartons or recycled PET shows brand responsibility—an increasingly important factor for eco-conscious shoppers.

➔ Volume & Shape Influence Perception: Standard 50ml cylindrical bottles strike the perfect balance between familiarity, ergonomics, and perceived value.

Key Components Of Tamper-Evident Eye Cream Packaging

Understanding what makes protective packaging tick is crucial when it comes to skincare jars and tubes. Let’s break down the essentials that keep your product safe and stylish.

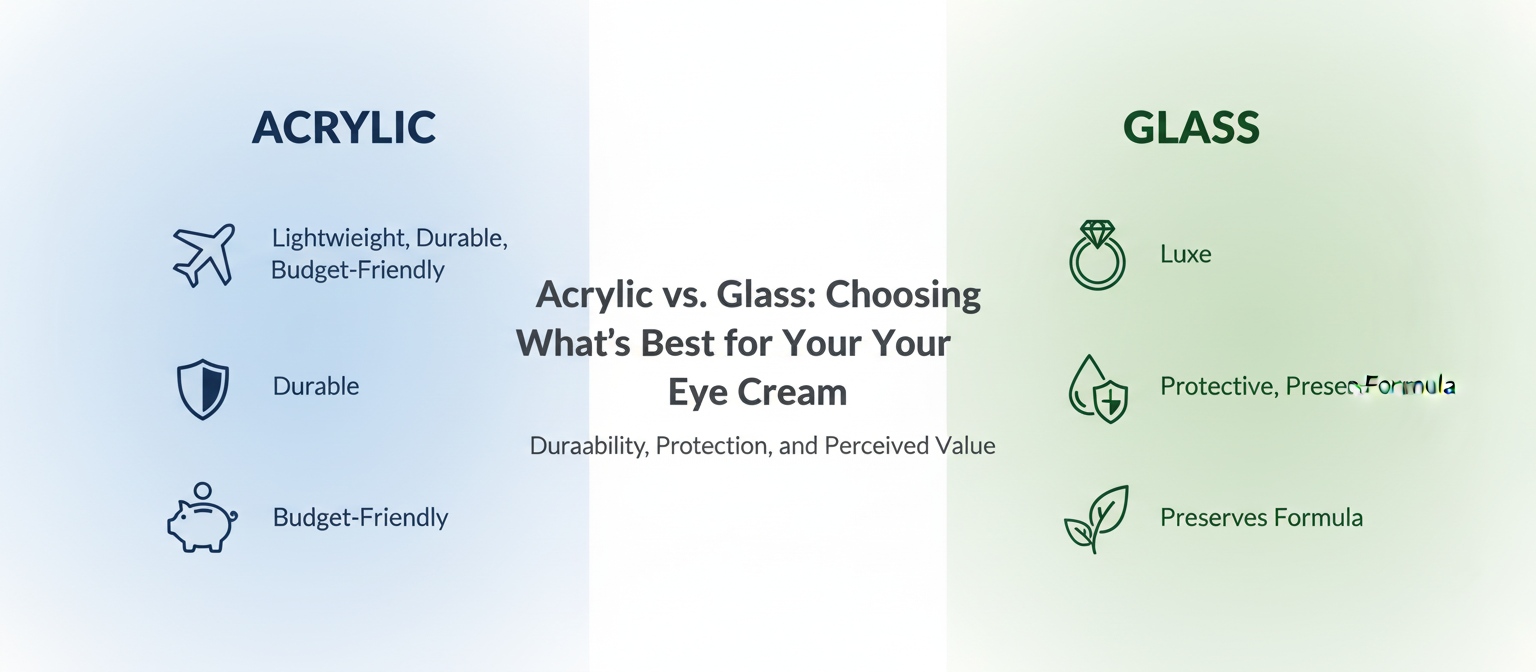

Acrylic vs. Glass: Material Choices Impacting Tamper-Evident Reliability

- Acrylic is lighter, more impact-resistant, and cost-effective—great for travel-friendly formats.

- Glass feels luxe, adds weight to the hand, and resists scratches better.

- For tamper protection:

- Glass pairs well with breakable closures, making any tampering obvious.

- Both materials support high-end finishes like frosting or metallization.

Choosing between them often boils down to whether you're aiming for portability or a high-end shelf presence.

Why Airless Pump Systems Enhance Sealing Performance

Airless systems are a game changer—here’s why:

- They block out oxygen completely, reducing oxidation risk.

- No dip tube means fewer entry points for bacteria.

- The internal vacuum mechanism keeps formulas fresh longer.

These pumps also work seamlessly with induction sealing, creating a dual layer of defense that discourages tampering while extending product lifespan.

Marriage of Safety and Style with Hot Stamping Decoration

• Hot stamping isn’t just about glam—it’s also practical when paired with a tamper-evident seal.

• Metallic foils applied over lids or logos can highlight disruptions if someone tries to open the container prematurely.

• It gives an upscale look while reinforcing security measures already in place.

That fusion of function and flair? It’s what today’s skincare buyers expect when picking up their next eye treatment tube or jar.

Selecting Your Ideal Volume from 15ml Samples to 100ml Retail Sizes

Short bursts of insight:

— Mini sizes like 15ml are perfect for trial runs or travel kits.

— Mid-range volumes around 30ml–50ml hit the sweet spot for daily users who want value without bulkiness.

— Larger containers at around 100ml suit spa-level use or long-term regimens but demand stronger seals like specialized films to prevent leaks during transit.

The right size doesn’t just affect convenience—it shapes how secure your product needs to be during storage and shipping too.

Achieving Premium Feel through Matte Textures and Soft Touch Coatings

Step-by-step breakdown:

→ Step one: Choose your base material wisely; matte coatings stick better on frosted acrylic than slick plastic blends.

→ Step two: Apply soft-touch finishes that give off that velvety vibe consumers associate with luxury skincare tubes.

→ Step three: Layer in tactile contrast by combining matte exteriors with glossy printed text using hot foil stamping techniques.

This combo doesn’t just elevate appearance—it subtly communicates quality before the jar even opens.

How Unique Identifiers Strengthen Consumer Trust in Eye Cream Packaging Security

This is where things get clever:

- A unique serial number printed under each jar helps trace batches during recalls or QA checks.

- QR codes link users directly to authentication pages—a simple scan confirms legitimacy.

- Holographic strips embedded into the closure area combine visual appeal with anti-counterfeit power.

- All these identifiers double as proof-of-origin tools while being nearly impossible to replicate convincingly without detection.

In short? These aren’t just bells and whistles—they’re trust builders hidden in plain sight.

4 Benefits Of Tamper-Evident Eye Cream Packaging

Tamper-evident designs aren’t just about safety—they’re a quiet powerhouse for trust, style, and shelf-life. Let’s break down how they work their magic.

Enhanced Product Integrity through Airless Pump Systems

Airless pumps are game changers for skincare tubes and jars. Here's why these slick dispensers matter:

- They keep out air, meaning fewer chances for oxidation or spoilage.

- The product stays untouched by fingers, cutting down the risk of contamination.

- They’re built to reduce waste—every last drop can be used.

This setup not only boosts product integrity, but it also makes customers feel like they're getting something clean and smartly designed. That’s a win-win.

Improved Brand Prestige: Metallic Color Finishes Impress Consumers

A sleek metallic finish does more than shine—it speaks volumes.

• Shiny golds and silvers scream high-end. People associate them with quality.

• In stores or on screens, reflective packaging catches the eye faster than matte options.

• It’s not just about looking good—metallic tones subtly signal brand protection by implying exclusivity.

In short? Fancy finishes elevate your prestige without saying a word.

Simplified Quality Checks with Transparent Color Choices

When containers are see-through or semi-clear, spotting issues gets way easier. One quick glance tells you if the cream's separated or discolored—no guesswork needed.

This helps both brands and buyers. For companies, it speeds up inspections during production runs. For shoppers? It builds consumer confidence because they can literally see what they’re getting before opening anything.

That kind of transparency is rare—and appreciated.

Elevated Perceived Value via Cylindrical Shaped Bottles

Cylindrical bottles don’t just sit pretty—they feel right in your hand too.

- Their symmetry looks intentional and polished.

- They fit neatly into vanity drawers or travel bags.

- The shape supports consistent labeling that wraps perfectly around the surface—no awkward creases here.

FAQs about Eye Cream Packaging

How does airless pump technology protect sensitive formulas?

- Keeps oxygen out, so ingredients stay potent longer

- Prevents contamination from fingers or outside air

- Delivers consistent doses without waste

This kind of system is especially helpful for eye creams with active ingredients like peptides or retinol—formulas that lose their punch if exposed too often.

Do finishes really affect how customers feel about your product?

Absolutely. Texture and appearance trigger emotional reactions before anyone reads the label. A soft-touch matte surface feels luxurious in hand, while scratch-resistant coatings keep containers looking fresh on crowded shelves. These small details whisper quality—and shoppers listen.

Is 50ml still the sweet spot for new launches in eye care lines?

Yes, and here’s why: it's big enough to suggest value but not so large that it feels risky to try something new near delicate skin. While 15ml works well for samples and travel kits, most consumers gravitate toward mid-size options when committing to daily use products like under-eye treatments.

Post time: Sep-30-2025