Ever stood in the lotion aisle, juggling a bulky bottle like it’s a weight-training session or squinting at a mini that barely lasts a weekend getaway? You're not alone. Today’s shoppers want options—fancy lotion bottles that fit their lifestyle like your favorite pair of jeans: comfortable, stylish, and just right. From 15 ml trial sizes to generous family-friendly 200 ml pump bottles, packaging isn’t just about looks anymore—it’s about purpose and connection.

Big brands are catching on fast. Why stick with cookie-cutter when you can customize? With smarter materials like PET and PCR plastics making even tiny containers feel luxe (without trashing the planet), the shift is clear: function meets flair. The question now isn’t if your packaging should change—but how quickly you can catch up before someone else steals your shelf space.

Key Points to Know Before Choosing Fancy Lotion Bottles

→ Capacity Ranges Matter: From 15 ml minis with droppers to 200 ml HDPE family bottles, size diversity supports varied user needs and usage occasions.

→ Smart Materials Lead the Way: PET, PCR plastic, HDPE, and glass offer durability, style, and eco-conscious options that appeal to modern consumers.

→ Closures Define Functionality: Pumps for daily use, droppers for precision—matching closure types enhances both usability and brand identity.

→ Custom Molds Add Edge: Unique bottle shapes through custom molds elevate shelf presence while supporting variable volume strategies.

→ Decorative Touches Sell Premium Appeal: Embossing, hot stamping, and metallic finishes differentiate fancy lotion bottles in a crowded market.

→ Eco Trends Drive Choices: Sustainability matters—materials like PCR plastic align with green values without sacrificing design flexibility.

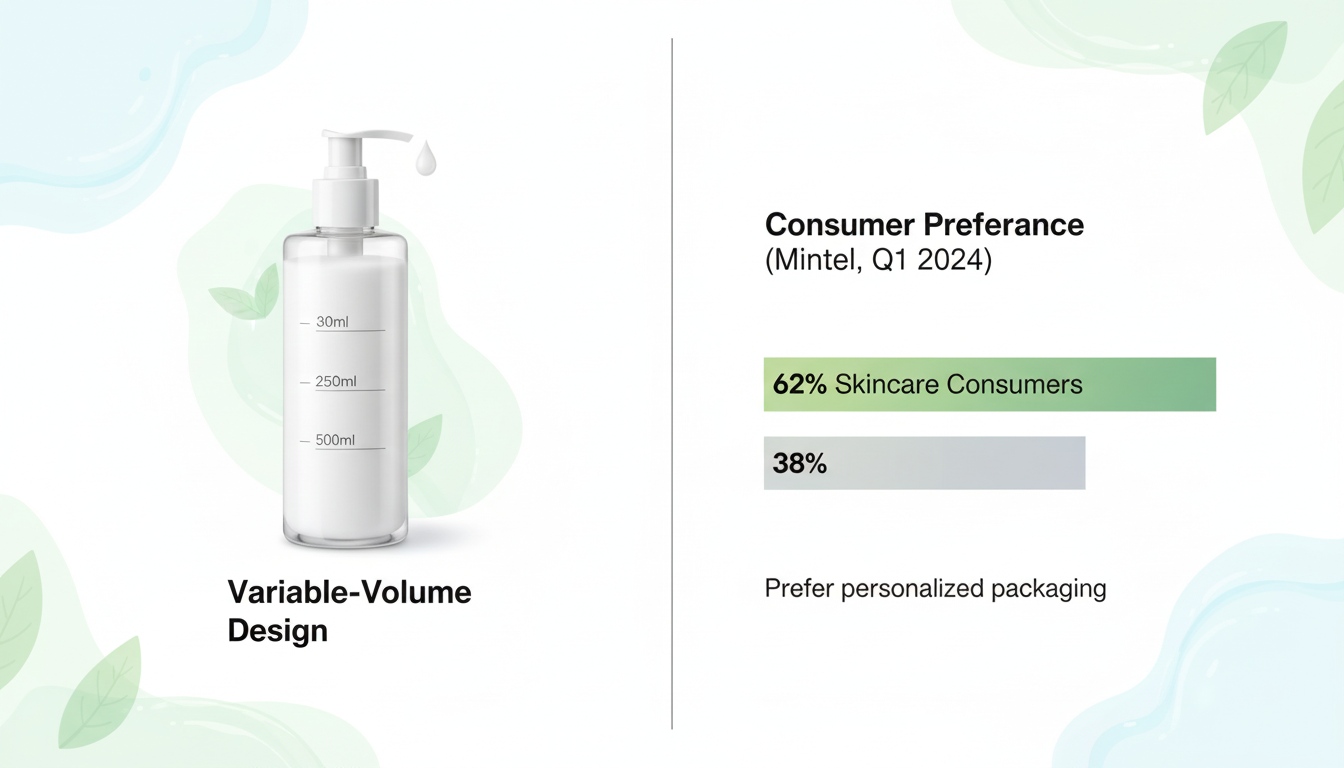

Why Variable-Volume Design Drives Fancy Lotion Bottles’ Future Growth

Today's lotion packaging game is changing. Brands are now blending variable-volume design with smart tech and eco-conscious choices to match shifting consumer preferences and market needs.

How PET and PCR Plastics Enable Flexible Volume Solutions

- PET is light, tough, and crystal clear—ideal for travel-sized or jumbo refill options.

- PCR (Post-Consumer Recycled) plastic offers the same flexibility while ticking the sustainable materials box.

- These materials cut down on shipping costs and carbon footprints thanks to their low weight-to-volume ratio.

- PET supports high-speed production lines without compromising structure.

- PCR resin blends allow brands to scale volume offerings affordably.

- Both materials are compatible with blow-molding tech for rapid customization.

• Easy to mold into multiple sizes

• Compatible with modern filling equipment

• Reduces packaging waste in supply chains

PET bottles can go from 30ml testers to full-size 500ml pumps without retooling entire lines—saving both time and money in manufacturing technology upgrades.

Mini bottles for gym bags, midsize ones for shelves, bulk refills for eco-shoppers—this flexibility keeps brands nimble in fast-moving market trends.

Custom Mold Designs Power Variable-Capacity Bottle Shapes

Grouped benefits of custom molds:

- Creative Control:

- Enables standout shapes that reflect brand identity.

- Allows ergonomic tweaks based on consumer usage feedback.

- Volume Versatility:

- A single mold can often accommodate several fill levels.

- Reduces tooling investment across product lines.

- Speed & Scalability:

- Faster prototyping means quicker launches.

- Supports seasonal or limited-run designs without major rework.

"According to Mintel’s Q1 Packaging Trends Report (2024), over 62% of skincare consumers prefer packaging that feels personalized or unique." That’s where custom mold work shines—it lets brands break away from cookie-cutter bottle silhouettes while still meeting practical size demands tied to varying routines or travel habits.

Eco Gains: HDPE and Glass Bottles Meeting Multiple Size Needs

Grouped material insights:

HDPE advantages:

• Lightweight yet strong—great for squeeze bottles.

• Easily recyclable in most municipal systems.

Glass advantages:

• Premium look boosts perceived value on shelves.

• Inert surface protects sensitive formulas over time.

| Material | Recyclability (%) | Common Sizes Supported | Consumer Appeal |

|---|---|---|---|

| HDPE | 90 | 50ml–1000ml | Functional, eco-smart |

| Glass | 75 | 30ml–500ml | Luxurious, reusable |

These two materials cater well to cost optimization, especially when paired with refill programs or minimalist branding strategies that reduce printing waste.

Different sizes let shoppers test new products without committing—or buy big once they fall in love. It’s all about meeting people where they are while keeping an eye on efficiency across the supply chain.

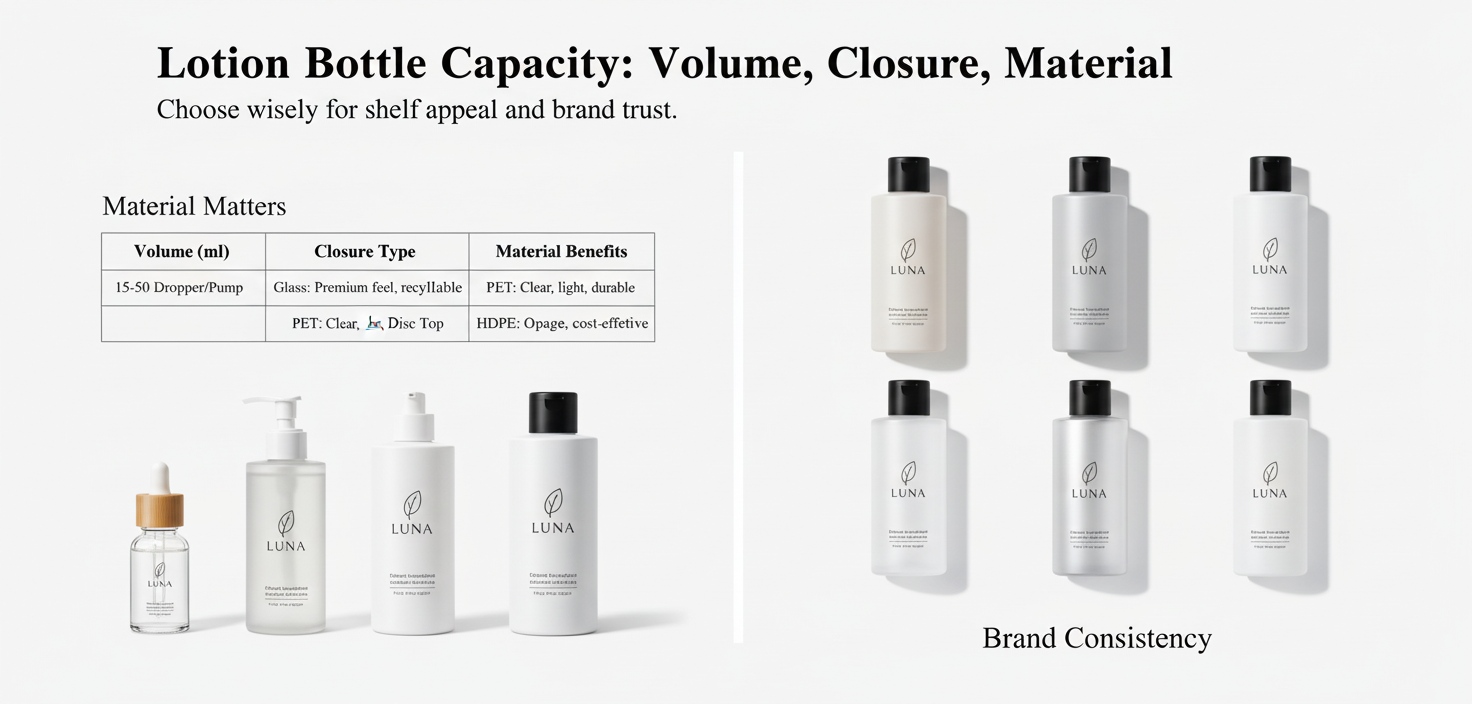

What Are Fancy Lotion Bottles’ Capacity Ranges?

A quick peek into the wild world of lotion bottle sizing—from pocket-sized cuties to family juggernauts, here's how these containers flex for every skincare scenario.

Compact Samples: 15 ml Bottles with Dropper or Screw Cap

- Great for:

- Trying out new formulas without commitment.

- Travel kits that don’t hog space.

- Targeted treatments like serums or eye creams.

- These smaller bottles often come in glass or durable PP plastic, keeping things lightweight and spill-proof.

- Dropper caps offer precision—ideal when you're working with potent ingredients like retinol or vitamin C.

• The screw cap variant is more budget-friendly and perfect for thicker lotions that don’t need measured dispensing.

These compact units are the MVPs of trial sizes, often seen in promotional kits or as part of deluxe samples. Their tight seals make them safe in handbags, and their petite size makes them ideal for on-the-go routines.

Tiny but mighty—these bottles hold just enough to test your skin’s reaction without wasting product. And honestly? They’re kinda cute sitting on your shelf too.

Mid-Range 30 ml–50 ml Bottles Featuring Pump Dispensers

Grouped by material and function:

Plastic Options (PET/PP):

- Lightweight

- Cost-effective

- Common in travel-size moisturizers

Glass Versions:

- Premium look

- Reusable/refillable

- Often used for high-end formulations

Pump Types:

- Lockable pumps for travel safety

- Airless pumps to prevent oxidation

- Standard press pumps for easy daily use

This range hits the sweet spot—small enough to toss into a gym bag, yet big enough to last weeks. The pump mechanism adds convenience while reducing mess, making it a favorite among both consumers and manufacturers looking to balance style with practicality in travel-size lotion bottles.

100 ml Options in Glass or PET with Flip Top Caps

Here’s where things get a bit more versatile:

- Glass gives off that luxury vibe—often used for boutique brands aiming for elegance.

- PET plastic is lighter and shatter-resistant, great if you’ve got butterfingers.

- Flip top caps are all about speed; pop it open, squeeze out what you need, snap shut—done.

• These bottles are often found in hotel amenities or mid-tier product lines where portability meets performance.

In this category, standard lotion bottle capacity meets everyday usability—you can leave one on your desk at work or keep it handy in your carry-on without triggering TSA alarms (yes, they’re under the liquid limit). Plus, they strike a nice balance between bulk storage and single-use wastefulness.

200 ml Family Sizes in HDPE with Labeling and Hot Stamping

| Bottle Material | Typical Use Case | Customization Type | Shelf Presence |

|---|---|---|---|

| HDPE | Family-size body lotions | Hot stamping | Strong & sturdy |

| PET | Thicker creams | Silk screen printing | Sleek & modern |

| LDPE | Squeeze lotions | Label wraps | Flexible & casual |

| Glass | Premium hair care | Embossing | Heavy & luxurious |

Big families? Big bottle energy. These beefy boys usually land on bathroom counters where everyone dips into the same tub of hydration joy. They're built tough with wide faces perfect for branding via hot stamping or full-wrap labels—because even large lotion bottle volumes deserve good design vibes.

HDPE takes the crown here—it’s sturdy without being heavy and holds up well against drops (kids love testing gravity). And when paired with pump tops? You’ve got yourself an efficient dispenser that lasts weeks before needing a refill—or longer if everyone stops overusing it!

Three Reasons To Choose Fancy Lotion Bottles Packaging

Smart packaging isn’t just about looks—it’s how your product speaks before it’s opened. Let’s break down why the right bottle makes all the difference.

Standout Metallic Embossing for Premium Appeal

• Adds tactile luxury that grabs attention on shelves and social feeds alike.

• Boosts brand image, making it instantly more high-end without changing the formula.

• Helps products stand out in saturated beauty aisles with a subtle shimmer and raised texture.

➊ Consumers associate metallic finishes with prestige, elevating perceived value.

➋ The embossed surface also enhances grip, improving function as well as style.

➌ For limited-edition lines, this finish becomes a visual signature.

✦ It’s not just shine—it’s storytelling through design.

This kind of finish doesn’t just decorate; it defines. When your bottle glints under store lighting or in an influencer's unboxing video, you're tapping into both visual drama and emotional response—two key drivers of modern consumer perception.

Ergonomic Pump Dispensers for Seamless Application

- Mess-free use? Check. One-handed operation? Double check.

- A good pump isn’t just about convenience—it reflects thoughtful design.

- That click-and-dispense motion adds to daily rituals, not disrupts them.

Let’s walk through why this matters:

Step 1: The shape of the pump head is contoured to fit fingertips naturally—no awkward angles.

Step 2: Internal valves regulate flow rate to avoid splatter or waste.

Step 3: Lock mechanisms prevent leakage during travel or shipping.

Grouped Benefits:

• Enhances dispensing mechanism reliability over time

• Reduces product oxidation by minimizing air exposure after each use

• Supports accessibility for users with limited dexterity

In short bursts or long pumps, every drop feels intentional—and that keeps users coming back.

Eco-Friendly PCR Plastic for Sustainable Packaging

| Material Type | Recycled Content (%) | Carbon Footprint Reduction | Consumer Preference (%) |

|---|---|---|---|

| Virgin PET | 0% | Baseline | 22% |

| Standard PCR | ~30% | -20% | 48% |

| High-Purity PCR | ~70% | -45% | 66% |

Choosing post-consumer resin (PCR) isn’t just good PR—it shows commitment to real change. These plastics reuse existing materials, cutting down waste while still delivering sturdy packaging performance.

Short Snippets:

– It's lighter on the planet and heavy on brand loyalty.

– Great for brands aiming to align with Gen Z values around sustainability.

– Compatible with most lotion formulas without compromising shelf life or look.

According to McKinsey's April 2024 report on sustainable packaging trends, “Brands using over 50% recycled content saw up to a 12-point lift in consumer trust scores.” That's no small win when customer confidence drives repeat buys.

Standard Vs. Variable Bottle Capacities

Quick peek into how consistent and flexible bottle sizes shake up production, branding, and consumer choice.

Standard Bottle Capacities

Standardized bottle sizing isn’t just about neat shelves—it’s about cutting costs, streamlining operations, and sticking with what works.

• Brands using standard bottle sizes benefit from predictable mold costs and simplified assembly lines.

• Storage and transport become easier when dimensions are uniform—fewer headaches for warehouse crews.

• Retailers prefer consistency; it keeps shelf layouts tidy and restocking a breeze.

Now toss in some tech: automated fillers can be calibrated once for mass runs without constant tweaking. That means fewer errors during filling, thanks to precise calibration aligned with global measurement standards.

But here’s the kicker—standard doesn’t mean boring. Even with fixed volumes like 100ml or 250ml, materials can vary wildly: glass for upscale appeal or PET for lightweight shipping. Each reacts differently under pressure during filling due to its unique material properties, so quality checks are essential before these bottles hit the market.

And on that note—no skipping on inspection routines! Rigid protocols ensure every container gets checked under strict quality control, especially if it's headed overseas where compliance rules get fierce.

Variable Bottle Capacities

When brands break away from cookie-cutter packaging, they open doors for creativity—but also complexity.

- Custom volume options let indie skincare lines stand out with quirky shapes or limited editions.

- Flexible capacity variations support seasonal promotions—think travel minis in summer or jumbo pumps during winter sales.

- Modular designs allow multiple sizes using a single base mold—saves money without sacrificing variety.

But here’s where it gets tricky: production lines must adjust frequently depending on fill volume, which means investing in adaptable filling technology that can handle shifts on the fly without spillage or waste.

| Capacity Range | Common Use Case | Material Impact | Fill Line Adjustment |

|---|---|---|---|

| <50ml | Travel packs | Requires high clarity | Minor |

| 100–150ml | Daily lotions | Balanced durability | Moderate |

| 200–300ml | Family-size formats | Needs impact resistance | Significant |

| >500ml | Bulk dispensers | Often HDPE | Major |

So yeah—it’s more work behind the scenes when you go off-script with sizing, but the payoff? A tighter grip on niche markets hungry for something fresh beyond standard lotion bottles… especially those who want their fancy skincare routine tailored down to the last drop size.

How To Select Fancy Lotion Bottles Capacity?

Picking the right bottle capacity isn't rocket science, but it sure makes a difference. Here's how to make that sweet spot choice.

Assess Volume Needs from 15 ml to 200 ml

• If you’re targeting trial users or travel kits, 15 ml or 30 ml works best—compact and low-cost.

• For daily personal use, 50 ml to 100 ml hits the mark without being bulky.

• Larger households or salon settings? Go with 150 ml to even up to 200 ml for fewer refills and better value.

Choosing volume isn’t just about aesthetics—it’s tied closely to usage frequency, available storage space, and buyer expectations.

Matching Closure Types – Pump, Flip Top or Dropper

- Pumps are perfect for thicker creams—they give controlled dispensing without mess.

- Flip tops suit lighter lotions where quick access matters.

- Droppers shine when the formula is oily or serum-like—great for precise application.

Always match your closure with both product texture and your audience’s customer preference. A silky lotion with a stiff pump? That’s a hard pass.

Material Selection: Glass, PET or HDPE

PET:

- Lightweight

- Shatter-resistant

- Great for colorful branding

HDPE:

- Super durable

- Good chemical resistance

- Often used for bulkier designs

Glass:

- Premium feel

- Recyclable

- Ideal when shelf appeal matters most

Your pick should juggle looks, cost, and how well it preserves the product's shelf life—especially if you're going organic or preservative-free.

Design Harmony with Surface Finish and Custom Color

A matte finish can scream luxury; glossy says clean and modern. Frosted glass gives off an artisanal vibe while clear PET shows off vibrant lotion hues beautifully.

Short bursts of design logic:

• Match color tones with your brand palette.

• Don’t forget tactile feel—texture matters as much as visuals.

• Consistency across sizes builds brand trust fast.

When all elements—from bottle shape to cap style—align visually, your packaging doesn’t just hold product; it tells your story. That’s where Topfeelpack really shines: helping brands turn ordinary containers into standout shelf candy.

FAQs about Fancy Lotion Bottles

What bottle sizes are most common for fancy lotions?

Lotion bottles aren’t one-size-fits-all. People reach for different volumes depending on how and where they use them:

- 15 ml: Perfect for samples or a quick trip—tiny, portable, often with droppers

- 30–50 ml: A sweet spot for daily routines; compact yet generous enough to last

- 100 ml: Elegant and practical, especially in glass or PET with flip tops

- 200 ml: The family favorite—roomy HDPE bottles that sit confidently on bathroom shelves

Each size tells its own story—from indulgent self-care rituals to everyday convenience.

How does the material of a lotion bottle affect its feel and message?

You can touch the difference. Glass feels cool and smooth in your hand—it whispers luxury before you even open it. PET is lighter but still clear, giving off a modern vibe without feeling cheap. HDPE has that soft matte texture many love; it's sturdy and familiar—a quiet workhorse behind the scenes.

The choice isn’t just about cost or recyclability (though those matter). It’s also about what kind of relationship you're building between product and person.

Why do brands care so much about custom-shaped bottles?

Because shape speaks louder than words. An oval silhouette might suggest elegance; square edges could say boldness or precision. Custom molds let brands create something instantly recognizable—even from across the room.

It’s not only aesthetics either—ergonomics come into play too. A well-designed curve makes holding and dispensing easier, turning routine into ritual.

Which closures actually make sense depending on the lotion type?Not all lotions behave alike—and neither should their caps:

- Thick creams need pump dispensers—you don’t want to wrestle with gooey textures.

- Lightweight serums benefit from dropper caps—they offer control down to each precious drop.

- Flip tops suit mid-weight formulas like body milk—quick access without mess.

Matching closure types with consistency isn't guesswork—it’s respect for both form and function.

Are there ways to decorate these bottles beyond basic labeling?Absolutely—and this is where things get personal. Hot stamping adds shimmering foil accents that catch light at just the right angle. Screen printing lets designs live directly on glass or plastic surfaces—not as stickers but as part of the object itself.

Embossing creates subtle raised textures you can feel under your fingertips—a tactile reminder that beauty lives in details you don’t always see right away but notice when it matters most.

Post time: Oct-02-2025