Square or round plastic bottles? When it comes to Cosmetic Packaging, your bottle’s shape could make or break the sale—literally.

Picture this: you’re strolling down the beauty aisle, eyes darting between rows of creams and serums. What grabs your attention first? Hint—it’s not the ingredients list. It’s the bottle. In a market where aesthetics sell faster than facts, choosing between square or round plastic bottles for Cosmetic Packaging isn’t just about looks—it’s about shelf appeal, shipping smarts, and how that packaging feels in someone’s hand at 7 A.M. on a Monday.

Brands don’t get second chances to make a first impression—especially when nearly 73% of consumers say packaging influences their buying decisions (2024 Statista Beauty Packaging Trends). So if your product’s dressed wrong for its audience? You’re basically showing up to prom in cargo shorts.

Key Points in Focus: The Shape of Success with Round Plastic Bottles in Cosmetic Packaging

→ Ergonomic Functionality: Round plastic bottles are favored for their comfortable grip and easy handling, making daily use more convenient for consumers.

→ Classic Appeal: Their timeless design resonates with traditional aesthetics, appealing to a wide range of beauty buyers.

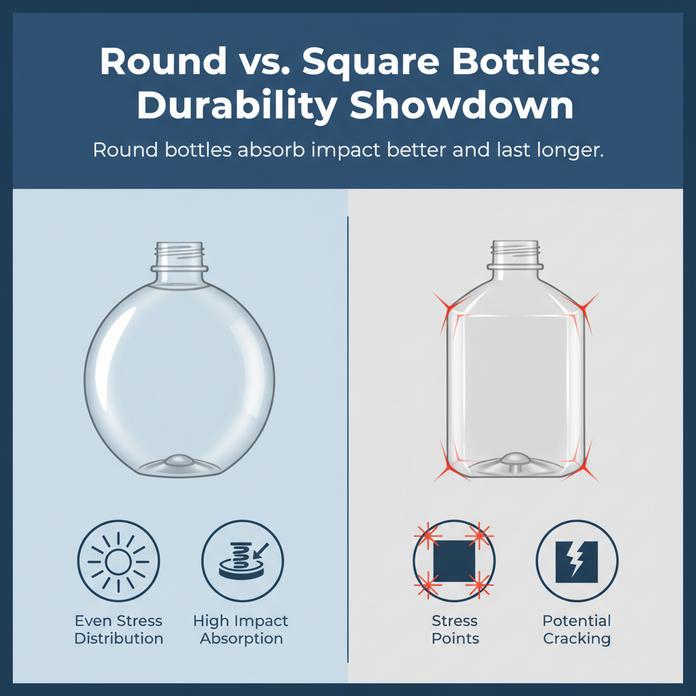

→ Durability Edge: Due to their curved shape, round bottles better distribute impact pressure, reducing the chances of breakage.

→ Consumer Preference Insight: Studies show that while square bottles offer modern flair, many users stick with round options for practicality.

→ Packaging Performance Balance: In cosmetic packaging, choosing between form and function often leads brands back to the reliable efficiency of round plastic bottles.

Understanding Cosmetic Packaging: Square Vs. Round Bottles

Choosing between square and round plastic bottles can shape how your product feels, looks, and functions on the shelf.

Key Features of Square Plastic Bottles

Square bottles don’t just sit pretty—they work hard behind the scenes.

• Their flat sides make labeling a breeze, giving brands more room for standout designs and clearer info.

• Thanks to their shape, they’re easier to line up neatly—hello, better space efficiency and lower storage costs.

• That flat surface also means better visibility for logos and text—huge win for bold branding opportunities.

→ On top of that, square bottles reduce empty spaces during shipping, cutting down overall shipping costs. It’s like packing a suitcase with zero wasted corners.

Bonus? Their sharp lines scream modern coolness—perfect if you’re going for that sleek, clean vibe on your shelf.

Round Plastic Bottles: Best for Functionality

Round plastic bottles are the go-to when ease-of-use trumps everything else.

- They fit snugly into hands—no awkward gripping required—which boosts their everyday appeal through solid ergonomics.

- The smooth curves help evenly distribute pressure, reducing breakage under stress—a hidden perk tied to smart pressure distribution design.

- They’re often cheaper to produce due to simpler molds—lowering overall manufacturing costs, especially at scale.

And let’s be honest: people love them because they just feel right when you pour or squeeze something out—true champions of consistent dispensing.

Design Trends: Square vs. Round Bottles

The beauty aisle is split—but not evenly.

Minimalism drives demand for clean lines and geometric forms; hence why square shapes dominate luxury skincare displays—they scream premium without saying a word.

But nostalgia sells too—and round containers carry that classic charm we all recognize from childhood shampoos or lotions.

Recent data from Mintel’s Q2-2024 Consumer Packaging Report shows that “consumers associate square packaging with innovation but still trust round shapes more when it comes to everyday use.” That explains why both styles continue thriving side by side despite different vibes.

| Bottle Shape | Shelf Appeal | Sustainability Score | Labeling Ease |

|---|---|---|---|

| Square | High | Medium | Excellent |

| Round | Medium | High | Good |

Ultimately, it depends on what message your product wants to send—and how much space you’ve got on store shelves or inside shipping crates.

Let’s not forget sustainability either; some brands like Topfeelpack are experimenting with hybrid forms that merge square edges with rounded grips—to get the best of both worlds while aligning with rising eco-conscious preferences around materials and recyclability standards in cosmetic packaging trends.

Five Advantages Of Square Plastic Bottles In Packaging

Square plastic bottles are changing the game for packaging, offering practical wins across production, branding, and shelf display.

Maximizing Shelf Space: The Square Advantage

- Shelf space is a hot commodity—especially for cosmetics. Square bottles slide into tight retail spots without wasting a sliver.

- Unlike round plastic bottles, square ones line up like puzzle pieces, boosting space utilization.

- Retailers love them because they keep displays neat and make it easier to organize by product type or brand.

- For warehouse storage? It’s all about that sweet storage optimization—you can stack more with less air between units.

- In small shops or crowded beauty shelves, every inch counts. That’s where square designs win big on packaging efficiency.

Cost-Effectiveness of Square Bottles in Production

According to Mintel’s Global Packaging Trends Report from early 2024, “brands are increasingly shifting toward efficient packaging forms that reduce waste while enhancing logistics.” That’s exactly what square bottles do:

- They cut down on excess material use during molding—less plastic waste means lower raw input costs.

- Their shape simplifies palletization and shipping calculations, leading to improved supply chain flow.

- For manufacturers using automated lines, the consistent angles of square bottles improve throughput speed and reduce machine jams.

The result? Lower total cost per unit without sacrificing quality—a win for both producers and eco-conscious buyers.

Versatility in Design: Square Bottles in Various Sizes

You’ve got options—tons of them.

▪️ Whether you’re bottling a travel-sized serum or a full-size lotion pump, square designs come through with flexible volume ranges.

▪️ This makes it easier to design cohesive product families under one packaging theme while still offering variety to customers who want compact vs full-size options.

▪️ From luxury skincare brands to indie makeup startups trying to stand out next to traditional cosmetic packaging, the versatility of sizes helps everyone play their own game.

And yes, those crisp lines offer way more freedom when it comes to cap styles and label formats too.

Enhanced Branding Opportunities with Square Designs

Square bottles aren’t just practical—they’re also prime real estate for your brand story.

• More flat surface area equals better label placement opportunities than you’d get on typical round plastic bottles. You can go bold with vertical logos or wraparound info panels without distortion issues.

• The angular silhouette naturally catches the eye on cluttered shelves—boosting visual appeal where it matters most.

• Want textured finishes or embossed logos? The flat sides make customizations easier during manufacturing—and more impactful once displayed.

• A strong shape supports strong identity: if you’re building a premium aesthetic or minimalist vibe, square designs help reinforce that perception through clean geometry and modern edge styling.

In short? They’re not just containers—they’re part of your marketing strategy too.

Durability Comparison: Square And Round Plastic Bottles

Which bottle shape takes more hits, lasts longer, and holds up under pressure? Let’s break down the real-world durability of these two cosmetic packaging champs.

Impact Resistance: Which Shape Holds Up Better?

• Round bottles tend to absorb shocks more evenly thanks to their curved walls. This makes them less likely to crack when dropped.

• The edges on square bottles create stress points where cracks often start during impact.

• In cosmetic packaging, shape isn’t just about looks—it plays into how well the bottle survives daily use and transit.

• For high-end products that travel often or sit in handbags, impact resistance matters as much as aesthetics.

• If you’re aiming for fewer returns due to product damage, round might be your go-to design.

• Bonus tip: Pairing a round bottle with thicker material boosts its toughness even more.

Material Thickness: A Key to Durability

Grouped by factor, here’s what determines how long your bottle lasts:

Wall Thickness

- Thicker walls = better resistance.

- Reduces chances of puncture or collapse under pressure.

Manufacturing Process

- Blow molding vs. injection molding affects uniformity.

- Quality control during production ensures consistent wall thickness.

Bottle Design

- Tapered necks can reduce weak points.

- Reinforced bases add structural strength.

Regardless of whether it’s a square or round plastic bottle, boosting the material thickness adds serious mileage to your packaging game—especially for travel-sized cosmetic items that get tossed around a lot.

Lifecycle Analysis: Longevity of Square versus Round Bottles

Let’s size up both shapes across key lifecycle metrics:

| Feature | Round Bottles | Square Bottles | Winner |

|---|---|---|---|

| Structural Integrity | High | Moderate | Round |

| Resistance to Warping | Strong | Weak at corners | Round |

| Environmental Exposure | Better stress spread | Higher degradation | Round |

| Reusability Rate | Higher | Moderate | Round |

Thanks to better stress distribution and fewer sharp angles, round designs typically edge out square ones in terms of longevity—especially in humid or fluctuating environments where plastic degradation accelerates over time. So if you’re gunning for sustainable cosmetic packaging that holds up over months or even years, circular wins the race more often than not.

Consumer Preferences: Square Vs. Round Plastic Bottles

Consumer tastes shift fast, but bottle shape still plays a surprisingly big role in buying decisions.

Aesthetic Appeal: What Shapes Do Consumers Favor?

Some folks go for looks, others for vibes—either way, cosmetic packaging shape speaks volumes.

• Square bottles often scream minimalism and sharp design. They’re trendy and Instagrammable, especially for newer skincare brands trying to stand out.

• In contrast, round bottles feel cozy and familiar. That soft curve has been around forever—and people trust what they know.

• Visual symmetry matters too. For shelf appeal, some say round wins because it’s easier on the eyes when lined up.

- Younger consumers aged 18–30 lean toward bold aesthetics—square shapes catch their eye more often during online shopping.

- However, surveys show that over half of buyers aged 35+ prefer round plastic bottles, citing nostalgia and simplicity as key reasons.

✦ Brands targeting premium markets tend to use square bottles to signal exclusivity and edge.

A recent BeautyStat report from Q1 2024 noted that “visual harmony between product design and brand identity boosts perceived value by up to 27%.”

Short bursts of preference:

- Square = sleek, modern edge.

- Round = comfort and tradition.

- Both have their fans; it’s about matching the vibe to the brand story.

Functionality Over Form: Consumer Insights on Practicality

When it comes down to actually using the product? Shape suddenly matters more than most think.

▸ Ease of grip: Many users say round bottles fit better in hand—especially when wet or soapy during application time.

▸ Storage efficiency: On the flip side, square bottles are praised for stacking neatly in drawers or cabinets without rolling around like marbles on hardwood floors.

▸ Dispensing control: Some consumers note that square shapes give better pump stability—less tipping over mid-use.

Grouped feedback from recent user testing:

Handling & Ergonomics

- Round shapes scored higher for comfort during everyday use.

- Square designs were slightly harder to hold with one hand during multitasking moments (like brushing teeth + applying serum).

Shelf & Bag Fit

- Square fits tight spaces better.

- Round rolls—but also slides easily into makeup pouches without catching edges.

Pump Performance

- Pumps mounted on square tops had firmer base support.

- Nozzle placement felt more intuitive on round-topped designs.

So yeah—practicality isn’t just about function; it’s about how your hand feels at 7 AM before coffee kicks in.

FAQs about Round Plastic Bottles

Why do people often prefer round plastic bottles for cosmetic packaging?

There’s something inherently comforting about a smooth, cylindrical shape. It fits naturally in the hand, making it easier to squeeze or pump out product with minimal effort. That tactile ease can turn a daily skincare routine into something almost ritualistic—familiar, fluid, and satisfying.

Do round bottles stand up well to everyday handling?

- Their curved design helps absorb pressure from accidental drops

- Stress is distributed evenly across the surface—less chance of cracks forming at weak points

- Most are made from flexible plastics that bounce back rather than break

In short: they’re built for life on bathroom counters and inside crowded makeup bags.

How does branding work on round vs square cosmetic containers?Square bottles offer more flat space—but there’s an elegance in wrapping text around a curve. Labels on round containers can feel more organic and less clinical. For brands focused on softness or natural beauty, this subtle visual cue matters far more than you’d think.

Is there much difference in cost between producing square and round plastic bottles?Round molds tend to be simpler to manufacture at scale:

- Less complex tooling means lower upfront investment

- Production lines run faster due to smoother rotation during fillingBut shipping efficiency sometimes favors squares—so it’s always a balancing act between production savings and logistics costs.

Can both shapes coexist within one brand without looking mismatched?Absolutely. Some brands use rounded designs for gentle cleansers or lotions while reserving squared edges for bold serums or high-impact treatments. The contrast becomes part of the story—a way of signaling purpose through form without saying a word.

Post time: Dec-04-2025