Ib Daim Ntawv Qhia Txog Kev Muaj Peev Xwm Tsim Khoom Hauv Topfeel

Lub peev xwm tsim khoom yog qhov qhia tseem ceeb rau txhua tus neeg tsim khoom npaj tsim khoom.

Topfeel ua tus thawj coj hauv kev tawm tswv yim lag luam ntawm "kev daws teeb meem ntim khoom kom zoo nkauj" los daws cov teeb meem ntawm cov neeg siv khoom hauv kev xaiv hom ntim khoom, tsim qauv, tsim khoom, thiab sib phim series. Siv kev tsim kho tshiab tas mus li thiab cov peev txheej tsim pwm, peb tau paub tiag tiag txog kev koom ua ke ntawm cov neeg siv khoom lub npe thiab lub tswv yim hom.

Kev tsim pwm thiab kev tsim khoom

Cov pwm yog ntau yam pwm thiab cov cuab yeej siv hauv kev tsim khoom lag luam rau kev txhaj tshuaj molding, tshuab molding, extrusion, die-casting lossis forging forming, smelting, stamping thiab lwm txoj hauv kev kom tau txais cov khoom xav tau. Hauv ntej, pwm yog ib qho cuab yeej siv los ua cov khoom zoo li tus kheej. Cov cuab yeej no muaj ntau qhov chaw, thiab cov pwm sib txawv muaj ntau qhov chaw sib txawv.

Cov pwm muaj pes tsawg leeg:

1. Cavity: yuav tsum tau siv tes polishing, siv S136 hlau nrog lub zog siab ntawm 42-56.

2. Cov hauv paus pwm: qhov nyuaj tsawg, yooj yim khawb

3. Punch: qhov uas ua rau lub raj mis zoo li cas.

4. Lub plawv tuag:

① Nws muaj feem xyuam rau lub neej ntawm cov pwm thiab lub sijhawm tsim khoom;

② Cov kev xav tau siab heev rau qhov kev ua kom raug qhov

5. Cov qauv swb: Sab laug thiab sab xis demoulding, cov khoom yuav muaj ib txoj kab sib cais, uas feem ntau yog siv rau cov fwj tshwj xeeb thiab cov hub uas nyuaj rau demould.

Lwm yam khoom siv

Lub tshuab sib tsoo

• Cov khoom siv meej tshaj plaws hauv tag nrho cov txheej txheem tsim pwm.

• Lub tshuab sib tsoo me me: tuaj yeem ua cov pwm puag ncig thiab plaub fab, siv cawv ua lag luam kom txias, ua haujlwm tes.

• Lub tshuab sib tsoo loj: tsuas yog siv cov pwm plaub fab xwb, feem ntau siv lub kaum sab xis ntawm lub hauv paus pwm; roj emulsified txias; kev siv tshuab.

Tshuab laum

Tshuab Drilling: ua cov qhov ntsia hlau ntawm cov pwm.

Tshuab milling: tshuab ua kom cov qhov ntsia hlau ntxhib, thiab tseem tuaj yeem txiav cov pwm.

Tshuab tapping tsis siv neeg: kev ua cov pwm xov

①Cov hniav ntawm cov hniav ntsia hlau zoo nkauj

②Qhov ntsug ntawm cov xov yog qhov zoo

Cov cuab yeej siv tshuab ib txwm muaj

- Ua cov pwm puag ncig, cov cuab yeej siv yog tungsten hlau, tungsten hlau siab hardness, me me hnav thiab tsim kua muag hauv kev siv, muaj peev xwm txiav tau zoo, tab sis brittle qauv, tsis yooj yim tawg.

- Feem ntau siv rau kev xuas nrig, qhov thiab lwm yam khoom puag ncig.

Cov cuab yeej siv tshuab CNC

- Cov pwm ntxhib. Siv cov tshuab txiav tungsten carbide, siv cov roj emulsified rau kev txias.

- Thaum txiav, sib dhos tag nrho cov cuab yeej (counterblade)

Cov txheej txheem tsim khoom thiab sib dhos

Cov txheej txheem sib dhos ntawm lub twj tso kua mis

Piston pas nrig, lub caij nplooj ntoos hlav, lub piston me me, lub rooj zaum piston, lub hau, lub phaj valve, lub cev twj tso kua mis.

Cov txheej txheem sib dhos ntawm lub taub hau twj tso kua mis

Tshawb xyuas-qhov chaw-muab tshuaj-nias lub twj tso kua mis lub plawv-nias lub taub hau twj tso kua mis.

Cov txheej txheem sib dhos ntawm cov straw

Cov khoom siv pub mis - pwm (ua yeeb nkab) - teeb tsa lub zog dej tswj lub raj txoj kab uas hla - txoj kev dej - cov quav ciab tawm.

Cov txheej txheem sib dhos ntawm lub raj mis airless

Ntxiv roj silicone rau hauv lub cev raj mis-piston-lub tes tsho xub pwg-lub raj mis sab nraud-sim qhov nruj ntawm huab cua.

Cov txheej txheem tsim khoom siv tes ua

Tshuaj tsuag

Siv ib txheej xim sib npaug zos rau ntawm qhov chaw ntawm cov khoom kom ua tiav qhov txiaj ntsig xav tau.

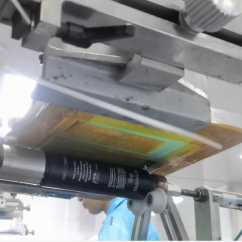

Kev luam ntawv npo

Luam tawm ntawm qhov screen los ua ib daim duab.

Kub stamping

Luam cov ntawv thiab cov qauv rau ntawm daim ntawv stamping kub hauv qab qhov kub thiab txias siab.

Kev sau ntawv lo

Siv lub tshuab los sau daim ntawv lo rau cov fwj.

Kev kuaj xyuas qhov zoo ntawm cov khoom

Cov txheej txheem tshuaj xyuas

Cov khoom siv raw

Kev tsim khoom

Ntim Khoom

Cov khoom tiav lawm

Cov qauv tshuaj xyuas

➽Kev ntsuas lub zogTorque = txoj kab uas hla ntawm cov xov / 2 (tsim nyog hauv qhov ntau ntawm ntxiv lossis rho tawm 1)

➽Kev kuaj viscosityCP (chav), qhov tuab dua ntawm cov cuab yeej kuaj, qhov me dua, thiab qhov nyias dua ntawm cov cuab yeej kuaj, qhov loj dua.

➽Kev sim teeb ob xim: kev xeem daws teeb meem thoob ntiaj teb ntawm daim npav xim, kev lag luam feem ntau siv lub teeb ci D65

➽Kev kuaj duab pom kevPiv txwv li, yog tias qhov tshwm sim ntawm lub dome tshaj 0.05 hli, nws yog qhov ua tsis tiav, uas yog, deformation lossis tsis sib npaug ntawm phab ntsa.

➽Kev sim tawg: Tus qauv yog nyob rau hauv 0.3 hli.

➽Kev sim rau cov menyuam: 1 yam khoom + 4 qhov kev ntsuam xyuas ntsia hlau, tsis muaj daim ntawv poob tawm.

➽Kev sim kub siab thiab qisQhov kev sim kub siab yog 50 degrees, qhov kev sim kub qis yog -15 degrees, qhov kev sim av noo yog 30-80 degrees, thiab lub sijhawm sim yog 48 teev.

➽Kev sim tiv thaiv kev sib txhuamTus qauv xeem yog 30 zaug hauv ib feeb, 40 qhov kev sib txhuam rov qab thiab tawm, thiab lub nra hnyav ntawm 500g.

➽Kev sim qhov nyuajTsuas yog cov ntawv gaskets tuaj yeem kuaj xyuas, lub chav tsev yog HC, lwm cov pwm hardness muaj cov qauv thiab lub kaw lus saib xyuas.

➽Kev sim tiv thaiv huab cua ultraviolet: Siv los ntsuas kev laus, feem ntau yog los saib seb puas muaj xim ploj thiab seb cov xim ploj mus li cas. 24 teev ntawm kev sim yog sib npaug li 2 xyoos nyob rau hauv ib puag ncig ib txwm muaj.