Isikhokelo soMgangatho woMveliso eTopfeel

Umthamo wemveliso luphawu olubalulekileyo kuyo nayiphi na imveliso ecwangcisiweyo yomenzi.

I-Topfeel ikhokela ekukhuthazeni ifilosofi yeshishini "yezisombululo zokupakisha izinto zokuthambisa" ukusombulula iingxaki zabathengi ekukhetheni uhlobo lokupakisha, uyilo, imveliso, kunye nokuhambelana kochungechunge. Sisebenzisa ubuchule obuqhubekayo betekhnoloji kunye nezixhobo zokuvelisa isikhunta, siqaphele ngokwenene ukuhlanganiswa komfanekiso webhrendi yomthengi kunye nengcamango yebhrendi.

Uphuhliso lwesikhunta kunye nokuveliswa

Iimbotyi ziintlobo ngeentlobo zeembotyi kunye nezixhobo ezisetyenziswa kwimveliso yemizi-mveliso zokubumba ngenaliti, ukubumba ngebhombu, ukukhupha izinto, ukubumba nge-die-casting okanye ukubumba nge-forging, ukunyibilikisa, ukunyathela kunye nezinye iindlela zokufumana iimveliso ezifunekayo. Ngamafutshane, imbotyi sisixhobo esisetyenziselwa ukwenza izinto ezimile okwemilo. Esi sixhobo senziwe ngamalungu ahlukeneyo, kwaye iimbotyi ezahlukeneyo zenziwe ngamalungu ahlukeneyo.

Ukwakheka komngundo:

1. Umqolo: kufuneka ukupolisha ngesandla, kusetyenziswa intsimbi ye-S136 enobunzima obuphezulu obuyi-42-56.

2. Iziseko zomngundo: ubunzima obuphantsi, kulula ukuzikrwela

3. Ukubetha: inxalenye eyenza imo yebhotile.

4. Umongo we-die:

① Inxulumene nobomi bokubumba kunye nexesha lokuvelisa;

②Iimfuno eziphezulu kakhulu malunga nokuchaneka komgodi

5. Ulwakhiwo lwesilayida: Ukususwa kwemveliso ngasekhohlo nasekunene, imveliso iya kuba nomgca wokwahlukana, osetyenziswa kakhulu kwiibhotile ezineemilo ezikhethekileyo kunye neejagi ezinzima ukuzisusa.

Ezinye izixhobo

Isixhobo sokugaya

• Izixhobo ezichanekileyo kakhulu kuyo yonke inkqubo yokuvelisa isikhunta.

• Isixhobo sokusila esincinci: singasebenza iimold ezingqukuva nezisikwere, sisebenzise utywala bemizi-mveliso ukuze siphole, sisebenze ngesandla.

• Isixhobo esikhulu sokugaya: phatha kuphela ii-molds ezisikwere, ikakhulu phatha i-engile ekunene yesiseko se-mold; ukupholisa ioyile exutyiweyo; ukusebenza komatshini.

Umatshini wokubhola

Umatshini wokugrumba: ukucubungula umngxuma wesikrufu sesikhunta.

Umatshini wokusila: imingxunya yezikrufu zomatshini wokusila orhabaxa, kwaye unokusika neenkuni.

Umatshini wokuthepha ngokuzenzekelayo: ukucutshungulwa kwemisonto yeenkuni

①Amazinyo ezikrufu acocekile

②Ukuqina komsonto kulungile

Izixhobo zoomatshini eziqhelekileyo

- Ukucubungula iimbumba ezijikelezileyo, isixhobo esisetyenziswayo yintsimbi ye-tungsten, intsimbi ye-tungsten enobunzima obuphezulu, ukuguguleka okuncinci xa kusetyenziswa, amandla okusika aqinileyo, kodwa ubume bayo bubuthathaka, bubuthathaka.

- Isetyenziswa kakhulu ekubetheni izithonga, ekufakeni imingxuma nakwezinye iindawo ezijikelezileyo.

Izixhobo zomatshini we-CNC

- Iimold ezirhabaxa. Sebenzisa i-tungsten carbide cutter, sebenzisa ioyile exutyiweyo ukuze upholise.

- Xa usika, lungelelanisa zonke izixhobo (i-counterblade)

Inkqubo yokuvelisa kunye nokuhlanganisa

Inkqubo yokuhlanganisa isiseko sepompo

Intonga yepiston, intwasahlobo, ipiston encinci, isihlalo sepiston, isiciko, ipleyiti yevalvu, umzimba wepompo.

Inkqubo yokuhlanganisa intloko yepompo

Intloko yepompo yokucinezela eyintloko-yokushicilela.

Inkqubo yokuhlanganisa umququ

Izinto zokutya-ukubumba (ukwenza umbhobho)-ukubeka umbhobho wokulawula uxinzelelo lwamanzi ububanzi-indlela yamanzi-ingca yokukhupha.

Inkqubo yokuhlanganisa ibhotile engenamoya

Yongeza ioyile ye-silicone kwibhotile yovavanyo lomoya olufana nomzimba, i-piston, ihlombe, umkhono wangaphandle, kunye nokuqina komoya.

Inkqubo yokuvelisa izinto zobugcisa

Ukutshiza

Faka umaleko wepeyinti ngokulinganayo kumphezulu wemveliso ukuze ufezekise isiphumo esifunekayo.

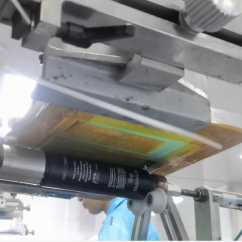

Ukuprinta isikrini

Ukuprinta kwisikrini ukuze kwenziwe umfanekiso.

Ukunyathela okushushu

Printa umbhalo kunye neepateni kwiphepha elishushu lokunyathela phantsi kobushushu obuphezulu kunye noxinzelelo oluphezulu.

Ukulebhelisha

Sebenzisa umatshini ukulebhelisha iibhotile.

Uvavanyo lomgangatho wemveliso

Inkqubo yokuhlola

Impahla engekasilwa

Imveliso

Ukupakisha

Iimveliso ezigqityiweyo

Imigangatho yokuhlola

➽Uvavanyo lweTorque: I-Torque = ububanzi beprofayili yomsonto/2 (ifanelekile ngaphakathi koluhlu lwe-plus okanye i-minus 1)

➽Uvavanyo lokuqaqamba: CP (iyunithi), okukhona isixhobo sovavanyo sityebile, kokukhona sincinci, kwaye okukhona isixhobo sovavanyo sinciphile, kokukhona sikhulu.

➽Uvavanyo lwesibane esinemibala emibiniUvavanyo lwesisombululo sekhadi lemibala yamazwe ngamazwe, umthombo wokukhanya oqhelekileyo weshishini i-D65

➽Uvavanyo lomfanekiso obonakalayoUmzekelo, ukuba iziphumo zovavanyo lwedome zidlula i-0.05 mm, kukusilela, oko kukuthi, ukuguquguquka okanye ubukhulu bodonga obungalinganiyo.

➽Uvavanyo lwekhefu: Umgangatho ungaphakathi kwe-0.3mm.

➽Uvavanyo lwerola: Imveliso e-1 + uvavanyo lwezikrufu ezi-4, akukho shiti iwelayo.

➽Uvavanyo lobushushu obuphezulu nobuphantsi: Uvavanyo lobushushu obuphezulu ngama-degrees angama-50, uvavanyo lobushushu obuphantsi ngama-degrees -15, uvavanyo lokufuma ngama-degrees angama-30-80, kwaye ixesha lovavanyo ngama-48 eeyure.

➽Uvavanyo lokumelana nokukralaUmgangatho wovavanyo uphindwe ka-30 ngomzuzu, ukungqubana okuya phambili nokuya phambili okungama-40, kunye nomthwalo oyi-500g.

➽Uvavanyo lokuqina: Zii-sheet gaskets kuphela ezinokuvavanywa, iyunithi yi-HC, ezinye ii-hardness molds zinemigangatho kunye nenkqubo yokubeka esweni.

➽Uvavanyo lokumelana nemozulu ye-Ultraviolet: Ukulinganisa ukwaluphala, ikakhulu ukubona ukutshintsha kombala kunye nokuphela kwenkqubo. Iiyure ezingama-24 zovavanyo zilingana neminyaka emi-2 phantsi kwemeko eqhelekileyo.