Njira yopangira zinthu zopangira pulasitiki mumakampani opanga zodzoladzola imagawidwa m'magulu awiri: kupanga jakisoni ndi kupanga blow.

Kupangira jakisoni

Kodi njira yopangira jakisoni ndi yotani?

Kupangira jakisoni ndi njira yotenthetsera ndi kusungunula pulasitiki (kutenthetsa ndi kusungunula kukhala madzi, pulasitiki), kenako n’kuika mphamvu kuti ilowe m’malo otsekedwa a nkhungu, zomwe zimathandiza kuti izizire ndi kulimba mu nkhungu, kuti ipange chinthu chokhala ndi mawonekedwe ofanana ndi nkhungu. Ndi yoyenera kupanga zinthu zambiri zokhala ndi mawonekedwe ovuta.

Makhalidwe a njira yopangira jakisoni:

1. Liwiro lopanga mwachangu, magwiridwe antchito apamwamba, magwiridwe antchito apamwamba kwambiri

2. Chogulitsacho chili ndi kulondola kwakukulu, ndipo cholakwika cha mawonekedwe ake ndi chaching'ono kwambiri

3. Kutha kupanga ziwalo zokhala ndi mawonekedwe ovuta

4. Mtengo wapamwamba wa nkhungu

Ambiri mwa ifebotolo lopanda mpweya, botolo la mafuta odzola okhala ndi makoma awiriamapangidwa ndi njira yopangira jakisoni.

Kuumba ndi nkhonya

Makhalidwe a njira yopangira nkhonya:

Pogwiritsa ntchito njira yachikhalidwe yopukutira galasi, kupukutira pogwiritsa ntchito mpweya wopanikizika wokhala ndi mphamvu inayake kuti upangitse ndikuziziritsa preform (thupi la pulasitiki lopangidwa ndi tubular) mu nkhungu kukhala njira yopangira zinthu zopanda kanthu. Ndi yoyenera kupanga zinthu zambiri zapulasitiki zopanda kanthu.

Kodi makhalidwe a njira yopangira zinthu zopsereza ndi ati?

1. Njira yosavuta yopangira, kupanga bwino kwambiri komanso zochita zokha

2. Kulondola kochepa

3. Pali zoletsa zina pa mawonekedwe a chinthucho

4. Mtengo wotsika wa nkhungu

Malinga ndi njira zosiyanasiyana zopangira ndi njira, kupanga ma blow molding kungagawidwe m'magulu atatu: extrusion blowing, injection blowing, ndi injection stretch blowing.

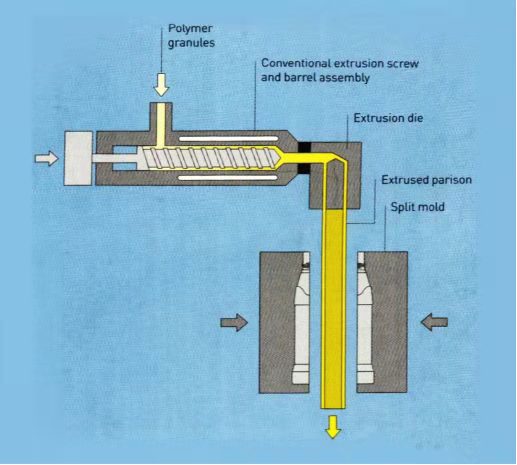

Choyamba ndi kufinya ndi kupukusa. Monga momwe dzinalo likusonyezera, kupukusa kwa extrusion kuli ndi magawo awiri akuluakulu: kupukusa ndi kupukusa.

Gawo loyamba ndi kutulutsa kutsekedwa kwa parison-mold.Chipangizo chotulutsira madzi chikupitirizabe kufinya kuti chipange parison ya tubular yopanda kanthu.Pamene parison yatulutsidwa kutalika koyenera, pamwamba pa parison imadulidwa kutalika koyenera chidutswa chimodzi, ndipo ziboliboli zomwe zili kumanzere ndi kumanja zimatsekedwa.

Gawo lachiwiri, kuyambitsa mpweya - kudula.Mpweya wopanikizika umalowetsedwa mu preform kudzera mu mandrel kuti utuluke.Chipindacho chimamatira kwambiri ku khoma lamkati la nkhungu kuti chizizire ndi mawonekedwe ake, ndipo chinthucho chimachotsedwa mu nkhungu, ndipo kudula kwachiwiri kumachitika.Mtengo wa zida zotulutsira ndi kupukutira ndi nkhungu ndi wotsika, ndipo mtengo wopanga nawonso ndi wotsika.

Komabe, kunyezimira kumachitika panthawi yopanga, ndipo pakamwa ndi pansi pa botolo zimafunika kudulidwa mwamakina kapena pamanja, ndipo nthawi zina pakamwa pa botolo pamafunika kupukutidwa ndi kudulidwa.

Mabotolo apulasitiki opangidwa ndi extrusion-blow ali ndi mzere wolekanitsa (linear protrusion) pansi, ndipo pakamwa pa botolo ndi pouma komanso si posalala, kotero ena ali ndi chiopsezo cha kutuluka kwa madzi. Mabotolo otere nthawi zambiri amapangidwa ndi zinthu za PE ndipo amagwiritsidwa ntchito mu zodzoladzola monga mabotolo a thovu, mafuta odzola thupi, ma shampu ndi zodzoladzola.

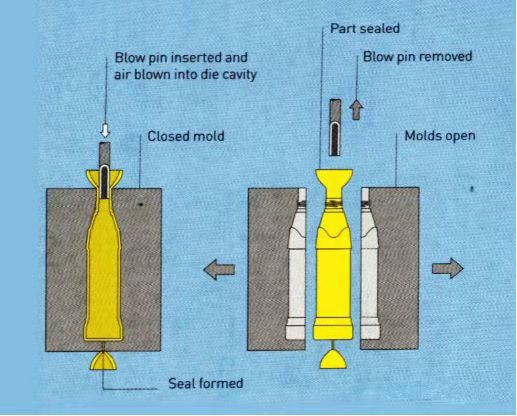

Mtundu wachiwiri ndi kupopera ndi jakisoni, komwe kuli ndi magawo awiri akuluakulu: kupanga jekeseni ndi jakisoni.

Gawo 1: Konzani kutseka kwa jekeseni ndi nkhungu.

Gwiritsani ntchito njira yopangira jakisoni kuti mupange parison yotsika pansi, ndipo cholumikiziracho chimazungulira 120° ku ulalo wopangira blow molding.

Chikombolecho chimatsekedwa, ndipo mpweya wopanikizika umalowetsedwa mu parison kudzera m'mabowo a mandrel kuti upange blowing.

Gawo 2: Konzani kuzizira kwa inflation ndi kuchotsa mphamvu.

Pambuyo poti chinthu chopangidwa ndi blow-mold chachiritsidwa bwino ndikupangidwanso, console imazungulira 120° kuti ichotse chinthucho. Palibe chifukwa chodulira kachiwiri, kotero mulingo wa automation ndi kupanga bwino kumakhala kokwera. Chifukwa botolo limapukutidwa kuchokera ku parison yopangidwa ndi jekeseni, pakamwa pa botolo ndi pathyathyathya ndipo botolo lili ndi mphamvu zotsekera bwino, mongaTB07 yopukutira mabotolo angapo.

Mtundu wachitatu ndi kukoka ndi kupukusa manotsi. Umagawidwa m'magawo atatu: kupanga jekeseni-kutambasula-kupukusa.

Mosiyana ndi mtundu wa jakisoni wopangidwa ndi jekeseni, jakisoni wotambasula umachitika pogwiritsa ntchito mzere wopangira zinthu.

Gawo 1: Konzani kutseka kwa jekeseni ndi nkhungu

Ikani preform yopangidwa ndi jakisoni mu blow mold

Ikani ndodo yotambasula ndikutseka nkhungu kumanzere ndi kumanja

Gawo 2: Kutambasula-Kuwomba-Kuziziritsa ndi Kuchotsa Mphamvu

Ndodo yotambasula imatambasulidwa motalikira, pomwe mpweya umalowetsedwa kudzera mu ndodo yotambasula kuti itambasulidwe mbali.

Kuziziritsa ndi kupanga mawonekedwe, kuchotsa ndi kuchotsa chinthucho

Kupaka jakisoni ndi njira yabwino kwambiri, yolondola komanso yotsika mtengo pokonza jakisoni.

Pakadali pano, pali njira ziwiri zopangira njira yopukutira jakisoni, zomwe zimatchedwa: njira imodzi ndi njira ziwiri. Kupukutira jakisoni ndi kupukutira jakisoni kumatsirizidwa pamodzi mu njira imodzi, ndipo njira ziwirizi zimamalizidwa paokha ngati njira ziwiri.

Poyerekeza ndi njira ya magawo awiri, njira ya gawo limodzi imamalizidwa mu zida za sitepe imodzi kuyambira pa zipangizo zopangira mpaka chinthu chomalizidwa. Njira yopangira ndi yosavuta ndipo kutentha kwachiwiri sikuloledwa, kotero kugwiritsa ntchito mphamvu kumakhala kochepa.

Njira ya magawo awiri imafuna jakisoni woyamba, kenako kukonza kwachiwiri pa makina opangira ma blow. Kupanga ma blow kumafuna kutentha kwachiwiri kwa preform yozizira, kotero mphamvu zimagwiritsidwa ntchito kwambiri.

Zambiri mwa izi zimachokera ku unyolo wogulira zinthu zokongola wa CiE

Nthawi yotumizira: Disembala-29-2021